- sale@instructrobot.com

- Dallas, TX , United States

In today's fast-paced manufacturing world, efficiency is key. A bag palletizing robot can greatly enhance productivity. These robots streamline the process of stacking bags, reducing manual labor. However, implementing them effectively requires careful consideration.

Understanding the specific needs of your operation is crucial. Not all bag palletizing robots are the same. Some are designed for larger bags, while others are more suited for smaller ones. The environment also matters; a robot that works well in one setting may struggle in another. It’s essential to assess these factors before making a decision.

While automation offers many benefits, it's not without challenges. Training staff to work alongside robots is critical. There may also be initial costs that need justification. Regular maintenance is necessary to avoid downtime. A bag palletizing robot can be a game-changer, but only if companies are prepared for the transition.

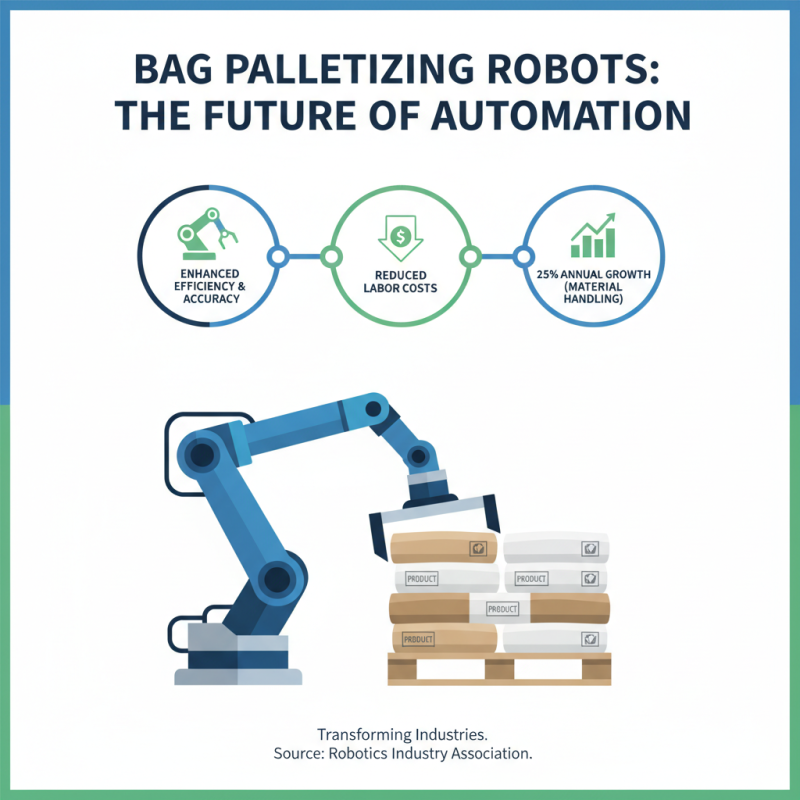

Bag palletizing robots are transforming automation in various industries. These robots enhance efficiency and accuracy while reducing labor costs. According to a report by the Robotics Industry Association, the use of robotics in material handling, including palletizing, is projected to grow by 25% annually.

Implementing bag palletizing robots can streamline operations significantly. They can handle heavy loads, working tirelessly without breaks. However, not all systems are perfect. Some may struggle with different bag sizes. This can lead to jams in the process, slowing down production. A study by the International Federation of Robotics suggests that companies should weigh the cost of these systems against potential downtime caused by malfunctions.

Training staff to work alongside these robots is crucial. Operators need to understand the technology to maximize efficiency. Yet, there is often resistance to change. Employees may worry about job security. Balancing automation with human touch can be challenging. However, when embraced, bag palletizing robots can lead to impressive gains in productivity.

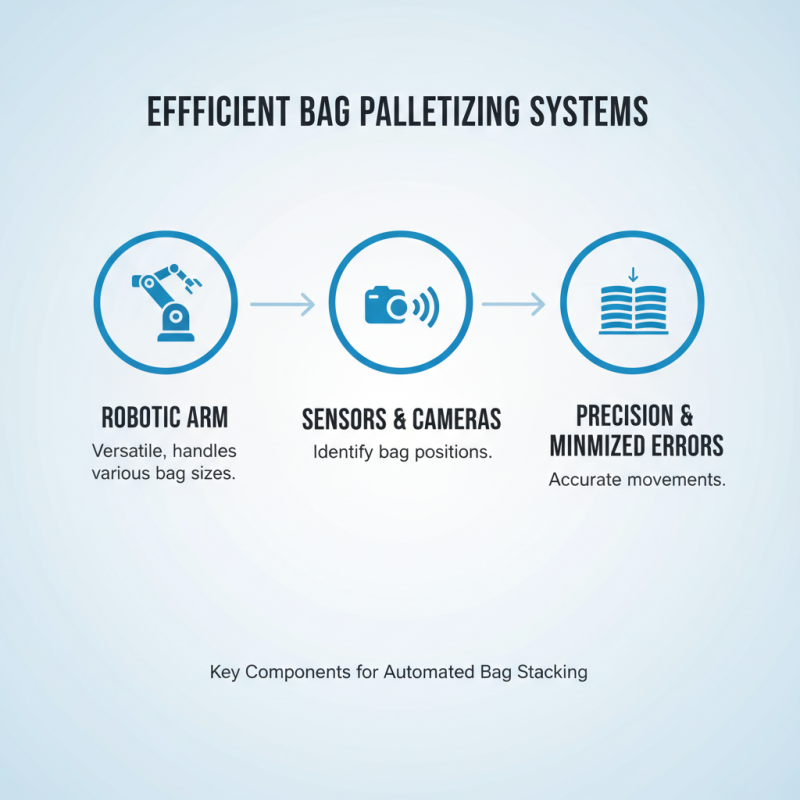

Efficient bag palletizing systems rely on several key components. A reliable robotic arm is crucial. It should be versatile to handle various bag sizes. Sensors and cameras enhance the robot's ability to identify bag positions. This helps in precise movements and minimizing errors.

Tips for optimizing your bag palletizing process: ensure your conveyor system is aligned well. Misalignment can lead to jams and slow operation. Regular maintenance of the robotic arm is essential. Dust and debris can obstruct its performance. Also, consider using software for predictive analytics. This helps anticipate maintenance needs and boosts efficiency.

The palletizing layout matters too. An organized layout minimizes the distance the robot must travel. It should allow for easy access to the bags. Space-saving designs can sometimes lead to confusion. Balancing efficiency and accessibility is key. Regularly review your operation setup. This ensures it evolves with changing demands.

When programming bag palletizing robots, clarity and precision are key. Start by defining the layout of the workspace. Knowing where each bag will be placed helps streamline the process. Use clear visual markers for operators. This can prevent confusion during high-speed operations. It's easy to overlook these details, leading to inefficiencies.

Focusing on the robot's movements is crucial. The path taken by the robot should be as direct as possible. Avoid unnecessary detours. If the programming isn’t optimal, it can slow down the entire operation. Test different paths and configurations. This experimentation may reveal areas for improvement.

Consider the types of bags being processed. Different weights and sizes can affect performance. Adjust settings accordingly to ensure smooth handling. It's essential to gather data on performance metrics regularly. Analyze this data for patterns that indicate potential issues. Continuous evaluation helps refine the programming over time.

Maintaining bag palletizing robots is crucial for ensuring optimal performance. These machines streamline warehouse operations and reduce labor costs. However, improper maintenance can lead to inefficiencies and downtime. According to a 2022 industry report, poorly maintained robots can result in a 25% decline in productivity.

Regular inspections can help identify potential issues. Check for wear and tear on mechanical components. Lubricate joints and bearings to reduce friction. This maintenance can prolong the robot's lifespan. Aim for scheduled maintenance intervals every six months. This practice minimizes unexpected breakdowns.

Another tip involves software updates. Outdated software can cause glitches. Keeping the system updated ensures better performance. AI-driven analytics can help monitor robot health. Use them to predict failures before they happen. Investing a little time can lead to significant gains in efficiency.

Implementing these strategies might not come easy. Sometimes, teams ignore warning signs until issues escalate. Reflecting on these challenges is important. Continuous training for staff can also enhance maintenance understanding. Efficiency is an ongoing journey, not a one-time effort.

In the rapidly evolving field of bag palletizing automation, trends are shifting towards enhanced efficiency and flexibility. A recent industry report highlighted that the global bag palletizing market is expected to grow at a CAGR of 5.2% from 2022 to 2027. This points to a significant investment in advanced robotics that can adapt to various packaging needs.

To optimize bag palletizing processes, consider utilizing robot arms equipped with artificial intelligence. These systems can learn from their environment, adjusting quickly to changes in bag sizes and weights. Regular maintenance is crucial, as overlooking it can lead to downtime. Simple checks can prevent inefficiencies.

Emphasis is also being placed on collaborative robots, or cobots. They work alongside human workers, enhancing productivity. However, training staff to operate new technologies remains a challenge. Investing in training programs can mitigate this concern. Data shows that companies that prioritize training see a 20% increase in operational efficiency.

Ultimately, staying abreast of trends will be vital for success in this area. As automation technology evolves, those willing to adapt will lead the market.

| Dimension | Value |

|---|---|

| Payload Capacity | 1000 kg |

| Max Speed | 1500 bags/hour |

| Footprint | 3m x 2m |

| Energy Consumption | 1.5 kWh |

| Control System | PLC based |

| Compatibility | Multiple bag sizes |

| Technology | AI and machine learning |