- sale@instructrobot.com

- Dallas, TX , United States

The integration of used robots into modern industries has emerged as a significant trend, reshaping the landscape of manufacturing and automation. According to a report by the International Federation of Robotics, the global market for industrial robots is expected to surpass $200 billion by 2025, with second-hand robots increasingly becoming a viable option for companies aiming to incorporate advanced technologies without the hefty price tag.

Used robots not only provide a cost-effective solution but also contribute to sustainability by reducing electronic waste and promoting a circular economy. As businesses seek to enhance efficiency and productivity, the adoption of used robots showcases innovative applications across sectors such as automotive, electronics, and logistics. This exploration of the benefits and innovations surrounding used robots highlights their potential to revolutionize operations and drive competitive advantages in a rapidly evolving industrial landscape.

Used robots not only provide a cost-effective solution but also contribute to sustainability by reducing electronic waste and promoting a circular economy. As businesses seek to enhance efficiency and productivity, the adoption of used robots showcases innovative applications across sectors such as automotive, electronics, and logistics. This exploration of the benefits and innovations surrounding used robots highlights their potential to revolutionize operations and drive competitive advantages in a rapidly evolving industrial landscape.

The rise of used robots in manufacturing industries marks a transformative shift that enhances productivity and efficiency. As companies seek cost-effective solutions without compromising quality, the adoption of second-hand robots has surged. These robots, once relegated to the sidelines, are now equipped with modern technologies through retrofitting and upgrading, making them suitable for a variety of applications. Industries are increasingly recognizing that these robots can be a reliable alternative, reducing initial investment costs while ensuring the capability to meet their operational demands.

**Tip:** When considering purchasing used robots, always check the robot's history and performance record. Understanding its previous applications can help determine if it suits your specific needs.

Moreover, the integration of used robots fosters a culture of innovation. By leveraging advanced software and artificial intelligence, companies can enhance the functionality of these robots, allowing for greater customization in manufacturing processes. This trend not only supports sustainability by extending the lifecycle of robots but also encourages businesses to invest in new technologies that complement their robot workforce.

**Tip:** Before integrating used robots into your operations, evaluate the compatibility of existing systems and the potential return on investment. This will help ensure a smooth transition and maximize productivity.

| Industry | Benefits of Used Robots | Innovations | Cost Savings (Estimated) |

|---|---|---|---|

| Automotive | Increased efficiency and production speed | Integration with AI for predictive maintenance | Up to 30% reduction in labor costs |

| Electronics | Improved precision in assembly | Advancements in robotic vision systems | Around 25% decrease in operational costs |

| Food & Beverage | Enhanced sanitation and efficiency | Robotics for automated sorting and packing | Can save 20% in labor-related expenses |

| Pharmaceutical | Increased accuracy in dosage | Smart robots for real-time data analysis | Potential reduction of 15% in costs |

| Logistics | Faster delivery through automated sorting | Drones for last-mile delivery solutions | Estimated savings of over 30% in delivery costs |

The financial landscape of modern industries is being reshaped significantly through the incorporation of used robots, driven by their cost efficiency. According to a report by Robotics Business Review, businesses can see a reduction of up to 40% in capital expenditure when opting for second-hand robotic systems. This is particularly advantageous for small and medium-sized enterprises (SMEs) that might find the high initial costs of new robots prohibitive. By investing in used robots, these companies can access advanced automation technology while conserving resources for other operational needs.

Furthermore, a study conducted by McKinsey & Company highlights that the total cost of ownership for used robots is often lower due to minimized maintenance and operational expenses. On average, upgraded used robots can deliver a return on investment (ROI) within 18 months, compared to an average of 24 months for new units. This accelerated ROI makes used robots a compelling option for industries looking to enhance productivity without overextending their budgets. As the demand for automation grows, the trend of acquiring used robots is likely to gain traction, providing a sustainable path for cost management and innovation.

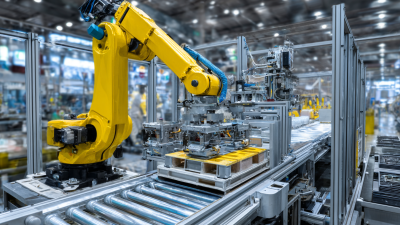

Used robots are proving to be invaluable assets in modern industries, particularly in enhancing productivity across supply chains. As companies increasingly seek cost-effective solutions to streamline their operations, the integration of refurbished robots into manufacturing and logistical processes has gained momentum. These robots not only reduce operational costs but also maintain high levels of precision and reliability, allowing businesses to meet rising demand without sacrificing quality.

Tips for Implementing Used Robots:

When considering the addition of used robots to your operations, it is crucial to assess their compatibility with existing systems. Conduct thorough evaluations of the robots’ capabilities and choose those that align with your specific needs. Additionally, investing in proper training for your staff ensures they can efficiently operate and maintain these machines. Regular monitoring of performance metrics will help you identify areas for improvement, ultimately leading to greater operational efficiency.

By leveraging the benefits of used robots, companies can optimize their supply chains, respond more flexibly to market changes, and enhance overall productivity. As the technology behind robotics continues to advance, industries that embrace these innovations will be well-positioned to thrive in a competitive landscape.

The integration of pre-owned robotics into modern industries offers substantial environmental benefits, aligning closely with the principles of sustainability. By utilizing used robots, companies can significantly reduce the carbon footprint associated with the manufacturing of new machines. This approach not only conserves energy and materials but also mitigates waste generation, as these robots can be refurbished and repurposed rather than ending up in landfills. The circular economy model encourages businesses to rethink their strategies towards resource consumption, focusing on longevity and efficiency.

In sectors like logistics and construction, the implementation of used robotics is proving to be a game changer. Research indicates that adopting pre-owned robots can streamline operations, enhance productivity, and contribute to a decrease in environmental impact. For instance, in logistics, hardware robots can optimize fulfillment processes while reducing the need for new manufacturing resources.

Furthermore, the construction industry, often criticized for its significant environmental footprint, can benefit from intelligent robotics that minimize waste during demolition and building processes. This innovative approach not only supports operational efficiency but also aligns with the growing demand for sustainable practices across various sectors.

The integration of used robots in various industrial sectors has demonstrated remarkable innovative applications that enhance productivity and streamline operations. For instance, a recent report by the International Federation of Robotics indicates that the market for used robots has surged, with a 30% increase in sales over the past year alone. Industries ranging from manufacturing to logistics are leveraging these cost-effective solutions to replace outdated equipment and boost efficiency. Companies like Amazon have adopted used robotics to optimize their warehouse operations, resulting in a 20% reduction in order processing time and a notable increase in throughput.

In the automotive sector, used robots are being repurposed for specialized assembly processes, allowing manufacturers to upgrade their production lines without incurring the hefty costs of brand-new systems. A case study showcased by the Robotics Business Review highlights how a major automaker reduced operational costs by 40% through the implementation of refurbished robotic arms. These robots not only improve precision but also enhance worker safety by taking over repetitive and hazardous tasks.

Tip: When considering the adoption of used robots, ensure thorough evaluation of their condition and suitability for your specific operational needs. Additionally, investing in training for staff to operate these robots can significantly enhance overall efficiency. Engaging in partnerships with suppliers who specialize in used robotics can also lead to tailored solutions that meet unique industry challenges.