- sale@instructrobot.com

- Dallas, TX , United States

In the rapidly evolving landscape of manufacturing, Fanuc industrial robots have become crucial. Dr. Emily Chen, a leading expert in robotic automation, states, “Fanuc industrial robots are transforming efficiency and precision in production lines.” Her insight highlights the potential of these advanced machines to optimize manufacturing processes.

Fanuc robots deliver numerous benefits. They enhance productivity, reduce human error, and can operate in hazardous environments. These robots are designed for flexibility, allowing manufacturers to adapt quickly to changing demands. However, the integration of Fanuc robots can pose challenges. Training employees to work alongside these machines is essential.

Adopting Fanuc industrial robots raises questions. What impact do they have on the workforce? Will certain jobs disappear? Balancing automation with human involvement is necessary. The journey towards full robotic integration may not be perfect, requiring thoughtful reflection on these aspects.

In modern manufacturing, industrial robots play a crucial role. They enhance productivity and efficiency significantly. These machines can work tirelessly, reducing human error to a minimum. Tasks like welding, painting, and assembly become quicker and more precise. This leads to shorter production times. Factories often see a boost in output with robots in play.

However, the implementation of industrial robots is not without its challenges. The initial investment can be high, which may deter some businesses. Additionally, training staff to work alongside these advanced machines requires effort and resources. There have been cases where integration did not go smoothly. Miscommunication between human workers and machines can lead to issues in workflow. Manufacturers must approach this transition carefully.

With effective planning, the benefits usually outweigh the negatives. Companies that embrace automation often find a competitive edge. The focus shifts to optimizing processes. Data gathered during production helps in refining operations. Robots can provide consistent results, reducing variability. These factors contribute to overall improvement in manufacturing practices.

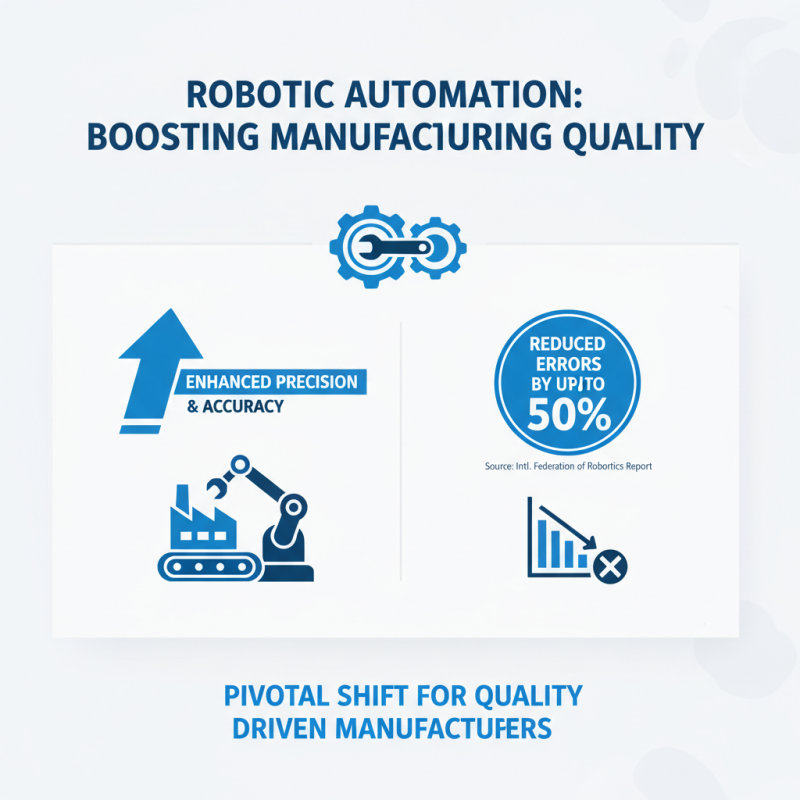

In modern manufacturing, enhanced precision and accuracy are critical. Industrial robots significantly contribute to these aspects. According to a recent report from the International Federation of Robotics, robotic automation reduces production errors by up to 50%. This marks a pivotal shift for manufacturers aiming for quality.

Consider assembly lines that require tight tolerances. A slight deviation can lead to costly defects. Robots equipped with advanced sensors can position components with an accuracy rate exceeding 0.01 millimeters. This level of precision ensures consistency. However, not all robots maintain this standard. Some require frequent recalibrations, which can disrupt production.

Moreover, while the accuracy of robots is impressive, human oversight is still needed. Machines might misinterpret certain signals or fail to adapt to unexpected changes. The integration of machine learning can enhance responsiveness. Still, the technology is not foolproof. Companies must remain vigilant and ready to innovate further. Balancing automation with human intervention creates a more reliable system for manufacturers.

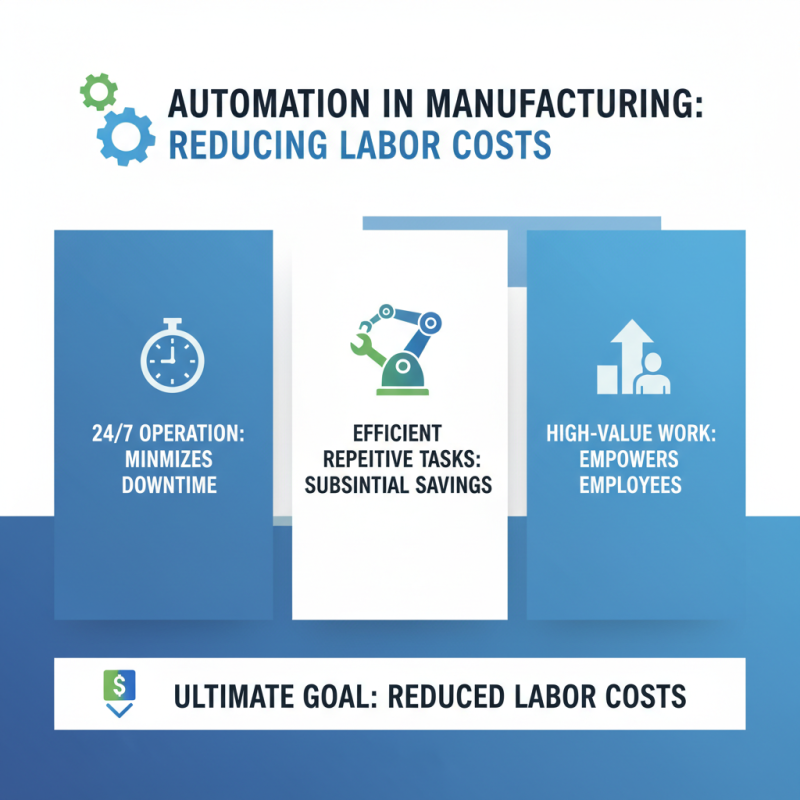

In modern manufacturing, reducing labor costs is crucial. Automation plays a key role in achieving this goal. Industrial robots can work 24/7, minimizing downtime. They handle repetitive tasks efficiently, leading to substantial savings. With less manual labor, companies can redirect resources to more complex tasks. This shift empowers workers to engage in higher-value operations.

Improved productivity metrics are another significant advantage. Robots enhance throughput by speeding up production times. They can operate with high precision, leading to fewer defects. This consistency boosts overall quality. However, the upfront investment in robotics can be daunting for smaller manufacturers. There may be a learning curve as teams adapt to new technologies.

Organizations must also consider the long-term benefits. While initial costs can be high, the return on investment often outweighs these expenses. Employees might fear job loss due to automation. Addressing these concerns is essential for a smooth transition. Communication and training can help workers embrace change and maximize the benefits of automation in manufacturing.

In modern manufacturing, increased production speed and efficiency are paramount. Industrial robots have emerged as key players in this evolution. According to a report from the International Federation of Robotics (IFR), the deployment of robots can boost production rates by up to 30%. This acceleration allows manufacturers to meet higher demand without compromising quality.

Robots can work tirelessly, executing tasks with precision. They enhance accuracy in repetitive processes, reducing error rates that often occur with manual labor. Some industries report a decrease in downtime by 25% after integrating robotic systems. However, not all implementations yield instant results. Companies must carefully assess their operational needs to avoid over-reliance on automation.

Additionally, skills gaps can pose challenges. Workforce retraining is essential to maximize the benefits of robotics. Without proper training, human workers may struggle to collaborate effectively with robotic systems. Balancing automation with a skilled workforce is crucial for long-term success. Overall, the integration of robotics into manufacturing lines offers significant advantages, but it also presents challenges that warrant reflection.

| Benefit | Description | Impact on Production |

|---|---|---|

| Increased Production Speed | Robots can perform tasks faster than humans, significantly reducing cycle times. | 20-50% increase in throughput. |

| Consistency and Quality | Robots deliver consistent performance, minimizing variability and defects. | Reduction in defect rates by up to 80%. |

| Reduced Labor Costs | Automation decreases the need for manual labor, leading to lower labor expenses. | Savings of 25-40% in labor costs. |

| Enhanced Workplace Safety | Robots can handle dangerous tasks, reducing the risk of workplace accidents. | Decrease in workplace injuries by 30%. |

| Flexible Production | Robots can be reprogrammed to handle different tasks without major changes. | Improvement in adaptability to market demands. |

| Remote Monitoring and Control | Operators can monitor and control processes from remote locations. | Increased operational efficiency and oversight. |

| Improved Production Flexibility | Robots can switch between products quickly, enhancing flexibility in production schedules. | Reduced downtime during product changeovers. |

| Energy Efficiency | Modern robots use less energy than traditional machines. | Energy savings of 20-30% in manufacturing processes. |

| Integration with Industry 4.0 | Robots integrate seamlessly with IoT and smart manufacturing systems. | Enhanced data collection and analysis for better decision making. |

| Global Competitiveness | Adopting robotics can improve a company's competitive edge in the global market. | Positioning in the market increases through innovation. |

In modern manufacturing, versatility is key. Industrial robots excel in various tasks, whether it's welding, painting, or assembly. These machines are designed to adapt to changing needs. Different industries benefit from their ability to handle diverse materials and tasks. For example, a robot used in automotive production may also be well-suited for electronics assembly.

Adaptability is not always perfect. Some robots struggle with complex shapes or delicate items. Adjusting to new processes can take time. Engineers often need to tweak settings to ensure optimal performance. This can lead to downtime, which factories wish to avoid. Yet, the flexibility these robots offer often outweighs these challenges.

Additionally, these machines can quickly learn new tasks. This reduces the time spent on training. However, this learning curve varies between different applications. Industries need to evaluate if the investment aligns with their specific needs. Despite imperfections, the potential for efficiency gains makes them an attractive option.

This bar chart illustrates the key benefits of using Fanuc industrial robots across various sectors in modern manufacturing. Each benefit demonstrates how these robots improve efficiency, reduce costs, and enhance flexibility in production processes.

Fanuc industrial robots offer a range of benefits that significantly enhance modern manufacturing processes. One of the primary advantages is their enhanced precision and accuracy, which lead to improved automation outcomes. Additionally, the implementation of these robots can result in substantial reductions in labor costs while simultaneously boosting productivity metrics. This is further complemented by increased production speed and overall efficiency on manufacturing lines, allowing companies to meet demand rapidly.

Moreover, the versatility and adaptability of Fanuc industrial robots enable them to be utilized across various industries, making them a valuable asset for manufacturers seeking to diversify their operations. The integration of these robots also enhances safety standards within the workplace, contributing to fewer accidents and a healthier environment for employees. Collectively, these benefits underscore the vital role that Fanuc industrial robots play in optimizing modern manufacturing.