- sale@instructrobot.com

- Dallas, TX , United States

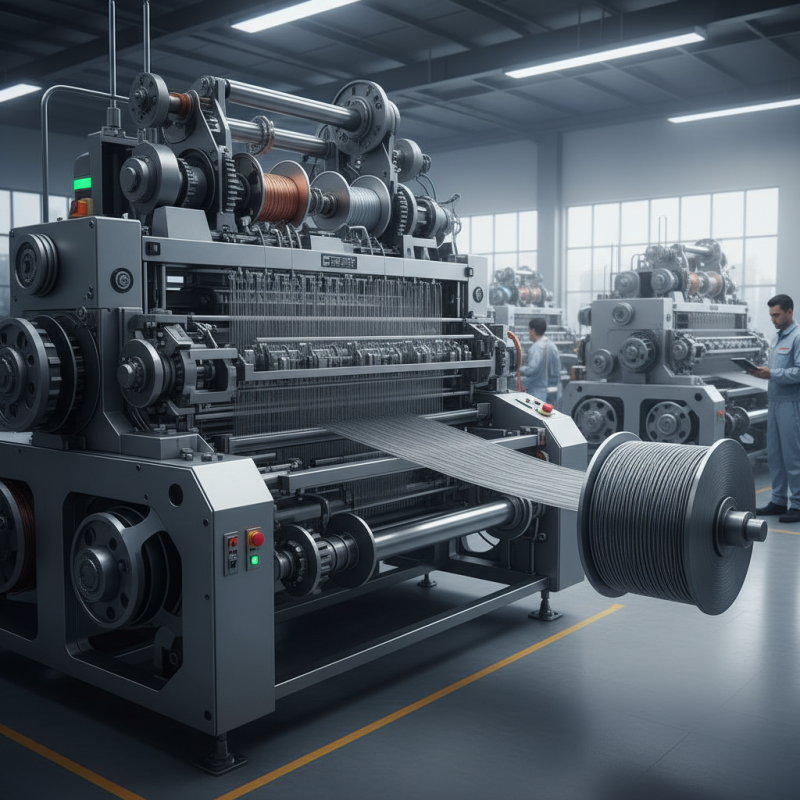

Choosing the best wire mesh weaving machine in 2026 can be challenging. Many factors impact this decision. The market offers various options, each with unique features and capabilities. Understanding these features is crucial for making an informed choice.

Consider the machine’s production capacity. Some machines specialize in high-volume output while others focus on quality. You may need to assess your specific needs, such as the type of wire mesh required. Not every machine will meet your demands, which might lead to unforeseen setbacks.

Price is another essential aspect. Inexpensive machines may not be durable or efficient. Investing in quality is often wiser, even if it means spending more initially. However, it’s easy to overlook the long-term benefits of reliable equipment. Take time to research and reflect on your priorities before making a purchase.

Choosing a wire mesh weaving machine requires careful consideration. The industry report from MarketsandMarkets estimates that the wire mesh market will grow significantly, projected at a CAGR of 6.5% through 2026. This indicates increased demand for various types of wire mesh, highlighting the need for efficient weaving machines.

One critical factor is the production speed of the machine. A machine that operates faster can enhance output but may increase wear and tear. It's essential to find a balance. Additionally, consider the machine's adaptability to different wire types and sizes. According to a study by Mordor Intelligence, flexible machines tend to perform better in fluctuating market conditions.

Another point to consider is the ease of maintenance. Machines that require frequent adjustments can slow down operations. It's important to evaluate the complexity of maintenance routines. A user-friendly design can reduce downtime, according to a recent review in the Journal of Manufacturing Processes. Moreover, understand the technological features offered. Advanced automation can improve precision, yet it may come at a higher cost. Think about long-term benefits versus initial investment.

When selecting a wire mesh weaving machine in 2026, it’s vital to explore available types. Different machines cater to diverse needs. Some machines focus on high-speed production. Others emphasize versatility for a variety of mesh sizes and styles. Each type has its pros and cons. Understanding these differences helps in making an informed choice.

There are machines for industrial uses and smaller models for crafts. Industrial machines often support larger rolls of wire. They can produce uniform mesh at high volumes. However, they require significant initial investment. Smaller machines are more affordable and easier to operate. But, they may lack the same production capacity. It’s essential to weigh these aspects carefully.

Another point to consider is the technology used in weaving machines. Some machines use advanced automation, improving efficiency. Others depend on manual controls, which can slow down production. Automation is often more reliable but can be complex. Simplicity might appeal but can limit capability. This balance between ease of use and functionality is crucial for buyers.

When selecting a wire mesh weaving machine, focus on key features. Look for machines with advanced technology that ensures precision. High-speed operation is essential for productivity. Automated controls can enhance efficiency, reducing human error. Ease of use matters too. A user-friendly interface will help operators adapt quickly.

Material versatility is another important factor. The best machines can handle various wire types and sizes. This flexibility will broaden your production capabilities. Check for durability and maintenance needs as well. Machines that require less frequent repairs save time and money.

Consider the machine’s adaptability for future innovation. As technology evolves, so should your equipment. Some machines may not keep up with future requirements. Investing in a forward-thinking design can prevent outdated processes. Ensure your machine aligns with your long-term goals for growth and efficiency.

When selecting a wire mesh weaving machine in 2026, comparing popular models is crucial. Various machines offer distinct features. Some excel in speed, while others focus on precision. A machine with high production capacity might not suit smaller operations. It's essential to assess your needs carefully. Ease of use is another vital aspect. Complicated interfaces can hinder productivity.

Durability is often highlighted by manufacturers, but performance in real-life scenarios can differ. Machines that appear sturdy may show wear sooner than expected. Regular maintenance is sometimes overlooked, impacting efficiency. Comparing customer reviews helps highlight potential issues. Pay attention to common complaints and commendations.

Automation features are trending, but they can introduce complexity. Some users find automated systems difficult to troubleshoot. Balancing technology with simplicity is key. Familiarizing yourself with different brands offers insights. Each offers unique specifications, and understanding these can help in making an informed choice. Take your time to explore options. The right machine can significantly affect production quality and profit.

When investing in a wire mesh weaving machine, maintenance and support play crucial roles. Regular maintenance ensures optimal performance and extends the machine's lifespan. According to industry reports, machines that receive consistent upkeep last up to 30% longer than those that don’t. Simple tasks, like cleaning and lubrication, can prevent costly breakdowns. Neglecting these tasks often leads to production delays and increased operational costs.

Support services also make a significant difference. A survey indicated that 75% of manufacturers prefer machines with readily available technical support. Quick access to spare parts and expert assistance reduces downtime. Moreover, operators must be trained to handle minor issues. This reduces dependence on external help and enhances productivity.

However, not every manufacturer offers adequate support. Choosing a machine with robust post-purchase care is critical. Some may promise extensive support but fail in practice. Users should diligently research actual customer experiences. Reviewing service quality should be as important as evaluating machine specifications. Balancing these factors leads to better long-term satisfaction with the purchase.