- sale@instructrobot.com

- Dallas, TX , United States

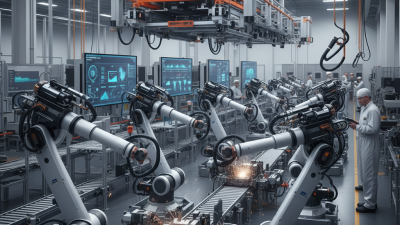

In today’s fast-paced manufacturing landscape, operational efficiency is vital. An industrial robot palletizer has become a game-changer for many businesses. According to a report by MarketsandMarkets, the palletizing robotics market is projected to grow from $3.1 billion in 2021 to $4.8 billion by 2026. This growth reflects a significant shift in how industries operate.

Implementing an industrial robot palletizer can reduce labor costs by about 25%. Companies often experience increased throughput and improved product safety. However, integrating these systems can be challenging. Some industries might face initial resistance to automation. The upfront investment and technical training may seem daunting. Failing to adapt could hinder productivity in the long term.

Despite these challenges, the benefits often outweigh the drawbacks. Case studies show that businesses using palletizers report lower damage rates and less downtime. However, it’s essential to evaluate whether your specific needs align with such technology. Reflection on unique operational goals is crucial before making a decision. In the end, the choice of an industrial robot palletizer might just usher in the efficiency your business needs.

Industrial robot palletizers are transforming manufacturing. They streamline the process of stacking products on pallets. This is crucial for increasing efficiency. Manual palletizing can be slow and error-prone. Human workers may become fatigued, leading to mistakes. Robots, however, work tirelessly and consistently.

By integrating these robots, businesses see significant benefits. They experience a boost in productivity and a reduction in labor costs. Labor shortages and high turnover rates are ongoing challenges. Robot palletizers can alleviate these issues. They can easily handle heavy loads and repetitive tasks, freeing up workers for more complex tasks.

While robot palletizers offer many advantages, some companies hesitate. Initial costs can be a barrier. There’s also the need for training staff to work alongside robots. Businesses must weigh these factors carefully. Technology can be intimidating. However, the long-term gains often outweigh the concerns. With careful planning, the transition can be smooth.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Increased Efficiency | Robot palletizers can work continuously without breaks, increasing throughput. | Higher production volume leading to better profit margins. |

| Consistency and Precision | Industrial robots operate with high accuracy, reducing errors and product damage. | Improved product quality and reduced waste. |

| Cost Savings | Reduction in labor costs and lower injury rates can lead to significant savings. | Lower operational costs and improved profit margins. |

| Flexibility | Modern palletizers can handle various package sizes and weights efficiently. | Adaptation to changing production needs and product lines. |

| Enhanced Safety | Robots can perform dangerous tasks, minimizing workplace injuries. | Safer work environment leading to higher employee morale. |

Industrial robot palletizers offer advanced solutions for various industries. They streamline the packing process and enhance productivity. One key feature is their flexibility; these robots can handle different package sizes and weights. They adapt easily to changing needs, which helps businesses stay competitive.

Another significant aspect is precision. Robot palletizers can place products with high accuracy. This reduces the risk of damages during handling. It also minimizes waste, which is crucial for maintaining efficient operations. Some models include vision systems for real-time feedback. They can identify misplaced items and adjust accordingly.

However, integrating these systems can pose challenges. The initial setup can be complex. Training staff is essential for maximizing efficiency. Over time, users may notice areas for improvement. Regular maintenance is necessary to ensure reliable performance. Automated systems should complement human workers, not completely replace them. Balancing automation with human oversight requires careful consideration.

When comparing manual and automated palletizing solutions, several compelling distinctions emerge. Manual palletizing often results in higher labor costs. Workers may struggle with fatigue and injury, especially during peak hours. In fact, studies show that the injury rate in manual palletizing can be as high as 35% in some warehouses. This creates not just health concerns but also productivity issues.

Automated palletizers, on the other hand, streamline the process. They can handle 1,800 cases per hour, while a manual worker typically manages about 300. This leads to significantly reduced labor costs over time. While the initial investment in automation may seem daunting, reports indicate that companies can see a return on investment in less than two years. However, maintenance of machinery can pose challenges. Unforeseen breakdowns can halt production, requiring companies to have contingency plans in place.

Moreover, automated systems can adapt to different product types with ease. However, they may struggle with irregular or delicate items. This is an area where manual labor can excel. In the end, the decision shouldn't be black and white. Evaluating specific needs and potential trade-offs is essential.

Implementing robot palletizers can transform your business operations. However, cost considerations are crucial. The initial investment can be significant. You might face uncertainties with installation and maintenance costs. Businesses must assess their immediate budgets versus long-term savings.

Integrating robotic systems can lead to efficiency gains. Labor costs can diminish over time, but the transition can be tricky. Training staff to work alongside robots requires time and resources. Not all employees may adapt easily to this technology shift. Additionally, robots need ongoing maintenance to function optimally, which adds to the budget.

Before committing, conduct a thorough cost-benefit analysis. This will clarify the financial implications over the long run. You may realize the savings will offset the initial expenses. Still, the decision should involve thoughtful reflection on both immediate and future needs. Every business’s journey will differ, so it's essential to evaluate your own path carefully.

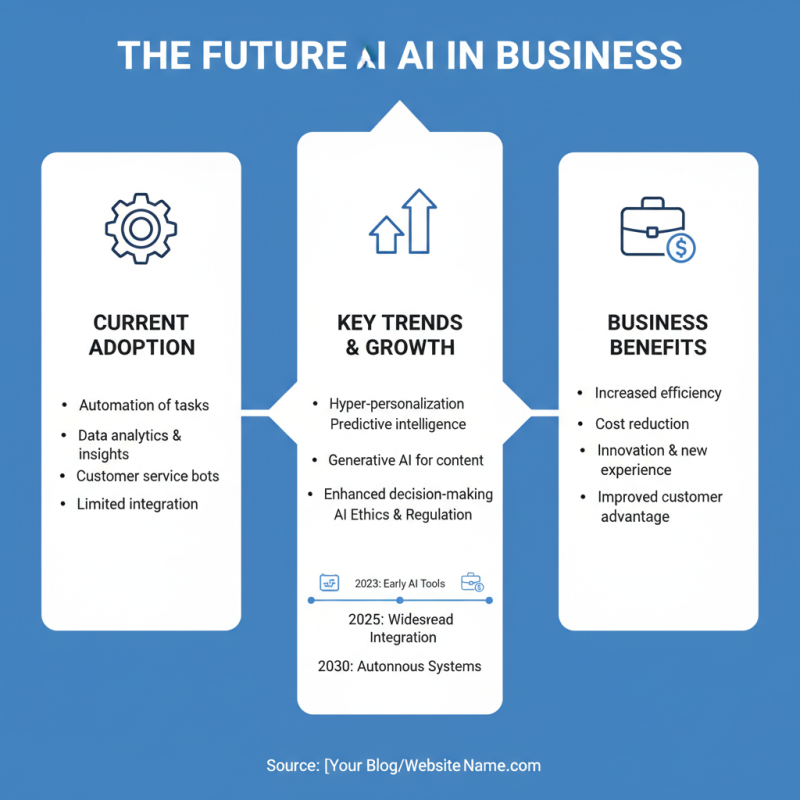

As industrial robotics evolves, palletizing applications are at the forefront of innovation. The focus on efficiency drives advancements in automation. Enhanced algorithms improve precision in stacking and handling products. These robots now adapt to varying product shapes and sizes, accommodating diverse operational needs. Flexibility is key in modern manufacturing settings, as businesses face fluctuating demands.

Future trends indicate a surge in collaborative robots. These machines work alongside human operators safely. They have sensors that detect presence, allowing for seamless integration in workflows. Furthermore, AI technology enhances their learning capabilities. Over time, robots will improve their stacking patterns, optimizing space and reducing waste.

Despite these advancements, challenges remain. Integration into existing systems can be complex. Not all facilities have the infrastructure to support new technologies. Training staff to work with robots is essential yet often overlooked. Businesses need to address these gaps to fully harness the potential of industrial robot palletizers. The future will require careful planning and consideration of both human and machine roles.