- sale@instructrobot.com

- Dallas, TX , United States

In the rapidly evolving landscape of warehouse operations, choosing the right material handling robots is crucial for enhancing efficiency and reducing operational costs. Experts agree that these technological solutions are more than just a trend; they represent the future of logistics and supply chain management. As noted by Dr. Jane Smith, a leading expert in automation technologies, "The right material handling robots can transform a warehouse from a labor-intensive environment into a streamlined, productive powerhouse."

Selecting the appropriate material handling robots involves assessing the specific needs of your warehouse, including layout, product types, and workflow patterns. By understanding the unique requirements of your operations, you can leverage the advancements in material handling technology to not only improve productivity but also to create a safer working environment for your employees. As we navigate this selection process, it’s important to consider factors such as scalability, flexibility, and integration with existing systems to ensure a sustainable solution that meets both current and future demands.

With numerous options available in the market, making an informed decision can be challenging. This guide aims to provide insights and best practices for selecting the best material handling robots tailored to your warehouse operations, ensuring that you maximize your investment and remain competitive in an increasingly automated world.

When considering the integration of material handling robots into your warehouse operations, it's essential to first identify the specific needs of your facility. Begin by analyzing the tasks that are most time-consuming and labor-intensive. Common operations such as order picking, sorting, and inventory management can significantly benefit from automation. Understanding the layout of your warehouse and the flow of goods will also help determine which areas could utilize robotic assistance effectively.

Next, assess the scale of your operations. Are you looking for robots to handle high volumes of items, or do you need solutions for smaller, specialized tasks? Consider the type of goods being moved; fragile items might require different handling methods compared to bulk materials. Additionally, evaluate your workforce's current skills and the potential learning curve for operating and maintaining these robots. Identifying potential integration points will lead to a more tailored approach, ensuring that the selected robots seamlessly align with your operational goals and ultimately enhance productivity.

| Robot Type | Payload Capacity (kg) | Operating Speed (m/s) | Battery Life (hours) | Integration Ease (1-5) |

|---|---|---|---|---|

| Automated Guided Vehicle (AGV) | 1500 | 1.2 | 10 | 3 |

| Collaborative Robot (Cobots) | 10 | 0.8 | 8 | 5 |

| Mobile Robot | 300 | 1.5 | 12 | 4 |

| Automated Palletizer | 2000 | 1.0 | 15 | 2 |

| Logistics Robot | 500 | 1.4 | 11 | 3 |

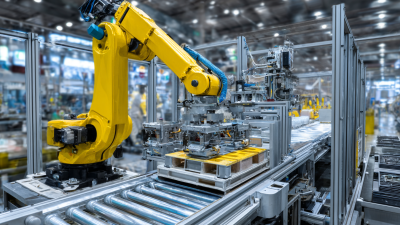

When evaluating different types of material handling robots for warehouse operations, it's essential to consider the specific tasks they will perform. Automated Guided Vehicles (AGVs) are ideal for transporting goods across designated routes, offering a reliable solution for repetitive tasks. They come equipped with sensors and software to navigate complex warehouse layouts while ensuring safety and efficiency. In contrast, Autonomous Mobile Robots (AMRs) have advanced navigation capabilities that allow them to dynamically map their environment and adapt to changes, making them suitable for more unpredictable workflows.

Another category to consider is robotic arms, which are designed for precise handling and manipulation of goods. These robots excel in tasks such as picking, packing, and sorting, providing high speed and accuracy. They can be programmed for various applications, making them highly versatile in a warehouse setting. Additionally, collaborative robots (cobots) can work alongside human workers, enhancing productivity without replacing jobs. Their ability to perform various tasks while ensuring worker safety makes them an attractive option for modern warehouses seeking to optimize their operations.

Ultimately, analyzing the specific requirements of your warehouse environment will help you select the most appropriate material handling robots. Consider factors such as load capacity, operational range, and integration with existing systems to make an informed decision that will enhance overall efficiency.

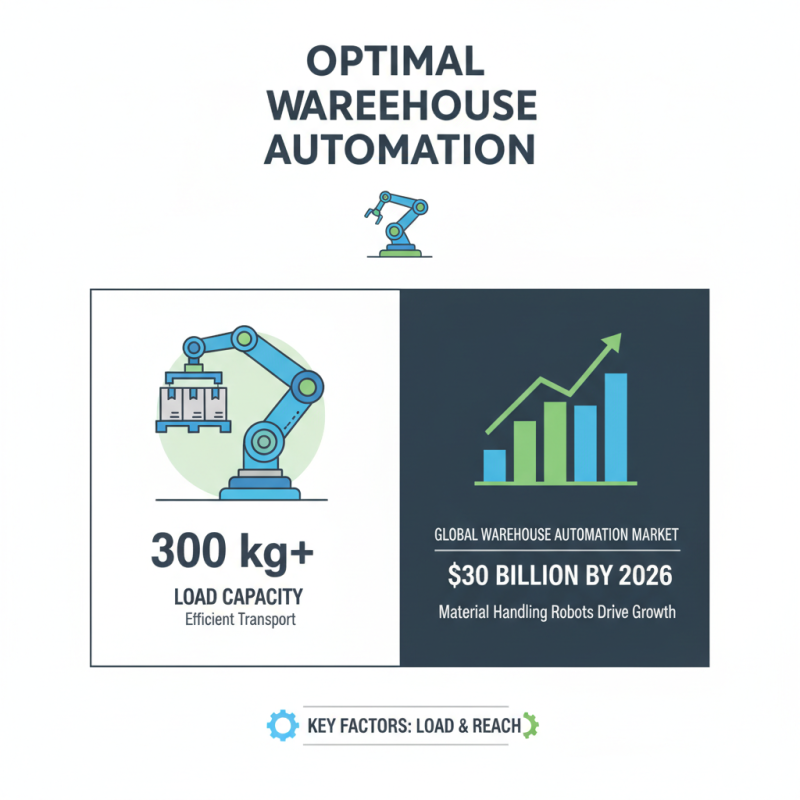

When selecting material handling robots for warehouse operations, assessing load capacity and reach is crucial to ensure optimal performance. According to a recent report by ResearchAndMarkets, the global warehouse automation market is projected to reach $30 billion by 2026, with material handling robots being a key contributor to this growth. Understanding the specific load capacity of robots is essential, as it directly impacts their efficiency in transporting products. For instance, a robot with a load capacity of at least 300 kg can handle a significant portion of common warehouse items, facilitating smooth operations and reducing manual labor.

Moreover, the reach of a material handling robot determines its ability to access various locations within a warehouse, maximizing productivity. A study by the Material Handling Industry of America (MHIA) indicates that robots with a reach of 2.5 meters can effectively navigate most aisle configurations in standard warehouses. This reach enables robots to access higher storage levels and transport goods efficiently, ensuring that operations run smoothly. Companies should consider both load capacity and reach when choosing robots, as balancing these factors can lead to improved safety standards, reduced operational costs, and enhanced overall efficiency in warehouse management.

In the realm of warehouse operations, the advancement of material handling robots is fundamentally transforming how businesses manage their logistics. The integration of automation features is pivotal, with the global market for warehouse automation projected to reach $30.5 billion by 2026, at a CAGR of 14.9% from 2021. This surge underscores the importance of selecting the right robotics technology that aligns with specific operational needs. Key automation features such as autonomous navigation, real-time inventory tracking, and the ability to interface seamlessly with existing warehouse management systems are crucial criteria for businesses aiming to enhance efficiency and reduce operational costs.

Moreover, the sophistication of robotics technology has evolved significantly, allowing for more versatile applications within warehouses. For instance, research indicates that robots equipped with advanced sensors and AI-driven algorithms can improve pick accuracy by up to 99.8%, which minimizes errors and streamlines order fulfillment processes. Furthermore, the implementation of collaborative robots (cobots) is on the rise, with a forecasted annual growth rate of around 31% over the next several years, according to industry analyses. This highlights the importance of evaluating not just the hardware but also the technological framework that supports interoperability and scalability in warehouse operations. Choosing the right material handling robots thus involves a careful consideration of these automation capabilities and emerging technologies to maximize productivity and adapt to the ever-evolving market demands.

This chart displays the load capacity of different types of material handling robots commonly used in warehouse operations. Understanding these capacities helps in selecting the appropriate robot for specific tasks within your warehouse.

When considering the implementation of material handling robots in warehouse operations, it is crucial to analyze the cost-effectiveness and potential return on investment (ROI). The initial investment can appear substantial, but when you break down the long-term savings in labor costs, increased efficiency, and reduced errors, the numbers may tell a different story. For example, by automating repetitive tasks, businesses can redirect human resources toward higher-value activities, ultimately driving productivity.

Tips:

Ultimately, by thoroughly evaluating these factors, businesses can make informed decisions about deploying material handling robots that drive significant ROI and position them competitively in the market.