- sale@instructrobot.com

- Dallas, TX , United States

Choosing the right industrial robot for your manufacturing needs is crucial. An effective robot can increase efficiency and productivity. However, the selection process is complex and requires careful consideration.

Different industries require different capabilities from industrial robots. Some tasks demand precision, while others focus on speed. Manufacturers must assess their specific needs to make informed decisions. Factors like workspace, budget, and available technology can complicate the choice.

Relying solely on specifications can lead to mistakes. Each robot has strengths and weaknesses. A robot that excels in one area may not perform well in another. Reflecting on the unique requirements of your production line is essential. Finding the right fit can be a challenge, but the rewards are significant.

Choosing the right industrial robot hinges on a clear understanding of your manufacturing needs. Start by analyzing the specific tasks your robots will perform. Tasks may include welding, painting, assembly, or packaging. Each task has unique requirements. For instance, painting robots need precision, while assembly robots require dexterity.

Industry reports indicate that robotic automation can increase productivity by up to 25%. However, selecting the wrong robot can lead to inefficiencies. Therefore, evaluate cycle times, load capacities, and reach specifications. By prioritizing these factors, you can align your robot’s capabilities with your production demands.

**Tip:** Involve your engineering team in the selection process. Their insights can bridge the gap between operational needs and technical specifications.

Another key aspect involves future scalability. Will your needs change over time? According to the International Federation of Robotics, 47% of manufacturers plan to increase automation in the next five years. Choosing a flexible robot allows you to adapt to shifting demands.

**Tip:** Consider modular designs. They provide an opportunity for upgrades without a complete overhaul. Always review your choices to ensure they meet both current and future operational goals.

| Robot Type | Payload Capacity (kg) | Reach (mm) | Application | Precision (mm) | Programming Interface |

|---|---|---|---|---|---|

| Articulated Robot | 20 | 1500 | Assembly | 0.05 | Teach Pendant |

| SCARA Robot | 10 | 800 | Pick and Place | 0.02 | GUI Software |

| Collaborative Robot | 5 | 1300 | Light Assembly | 0.1 | Easy Interface |

| Delta Robot | 6 | 700 | Packaging | 0.005 | Vision System |

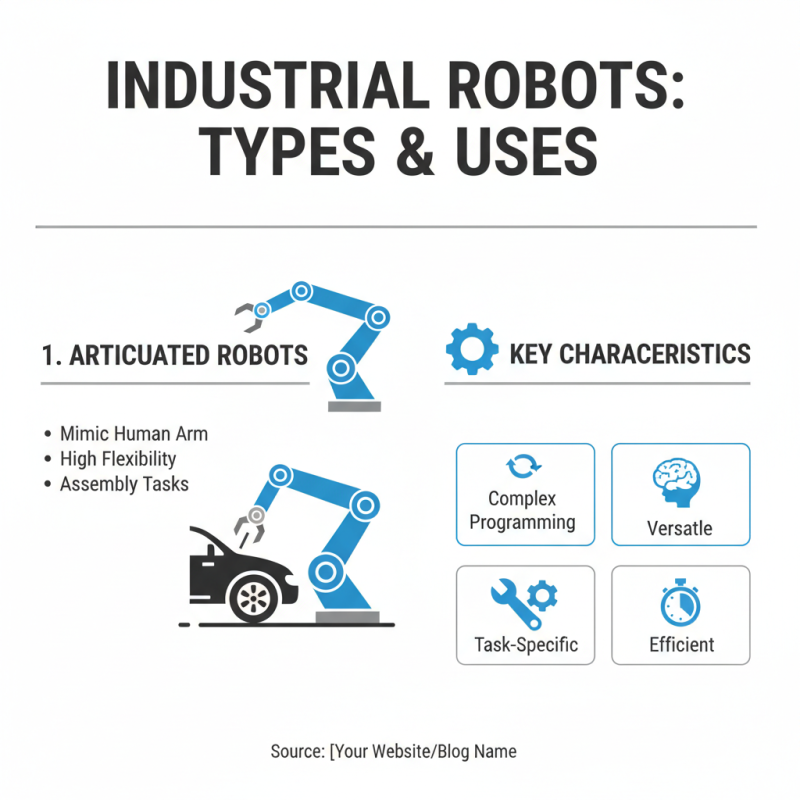

Industrial robots come in various types, each serving unique purposes in manufacturing. Articulated robots are popular for their flexibility. They can easily mimic human arm movements, making them ideal for assembly tasks. However, they require proper programming for specific tasks, which can be a challenge.

Then, there are SCARA robots. They excel in tasks like pick-and-place operations. Their rigidity allows for precise movements, but they lack the versatility of articulated robots. Users sometimes find them unsuitable for complex applications. Collaborative robots, or cobots, work alongside humans. They increase efficiency and safety, but proper safety measures are essential to prevent accidents.

Choosing the right robot isn’t always straightforward. Companies must assess their specific needs. The wrong choice can lead to inefficiencies or accidents. Evaluating the production process thoroughly is crucial. Reflecting on past choices can refine future decisions. This insight can guide in selecting the best industrial robot.

Choosing the right industrial robot requires careful evaluation of key features that align with specific manufacturing needs. A recent report by the International Federation of Robotics indicates that over 2.7 million industrial robots are in use globally. This statistic highlights the increasing reliance on automation. However, with so many options available, identifying the right features becomes essential.

When assessing robots, consider payload capacity, reach, and precision. Robots with high payload capabilities allow for diverse applications. A study from the Robotics Industries Association shows that companies often underestimate the weight of their part requirements. This oversight can lead to operational issues and increased costs down the line. Additionally, reach is critical; a robot that cannot access certain areas will limit productivity. Precision is non-negotiable as even small deviations can lead to significant quality issues.

It’s also vital to evaluate software capabilities. Advanced processing power and user-friendly interfaces streamline operations. However, some manufacturers may find cutting-edge software complicated. Employees may need extra training, which can slow down initial setup times. Balancing technology integration with training requirements is crucial for maximizing investment in automation.

When considering industrial robots, budget and cost-effectiveness are critical. Various reports indicate that businesses often overlook long-term costs in favor of initial price. For instance, a study by the International Federation of Robotics revealed that operational costs can be greater than purchase costs over five years. Operators must focus on total cost of ownership (TCO).

Analyzing TCO involves assessing maintenance, energy consumption, and software upgrades. A robot might be cheap upfront but expensive to operate. For example, energy-efficient models can cut energy costs by up to 30%. Conversely, a low-cost model may require frequent repairs, undermining savings.

Many manufacturers also fail to factor in training costs. An operator's learning curve can span weeks. This delay may reduce productivity. Additionally, potential downtime during the implementation phase affects the overall budget. Users might want to consider training and integration as hidden costs. Ignoring these factors can lead to budget overruns and operational inefficiencies.

Planning for future scalability in your workflow requires foresight and adaptability. When choosing an industrial robot, consider your production goals. Think about how many units you'll need to produce over time. A flexible robot can adapt as demands change. It’s crucial to select a robot that can handle multiple tasks. This reduces the need for constant upgrades.

Integration is another key factor. The robot should fit seamlessly into your existing systems. This includes software and hardware. Sometimes, adding a new robot can disrupt workflow. It’s essential to review current processes before implementation. Don’t ignore potential hiccups during integration. Ensure that team members are trained to work with the new technology.

Think about future trends as well. Automation is constantly evolving. What works today may not be sufficient tomorrow. Be prepared to reassess and upgrade as needed. It's important not to rush this decision. Take the time to evaluate how a robot aligns with your long-term objectives. Balancing immediate needs with future possibilities is vital for success.