- sale@instructrobot.com

- Dallas, TX , United States

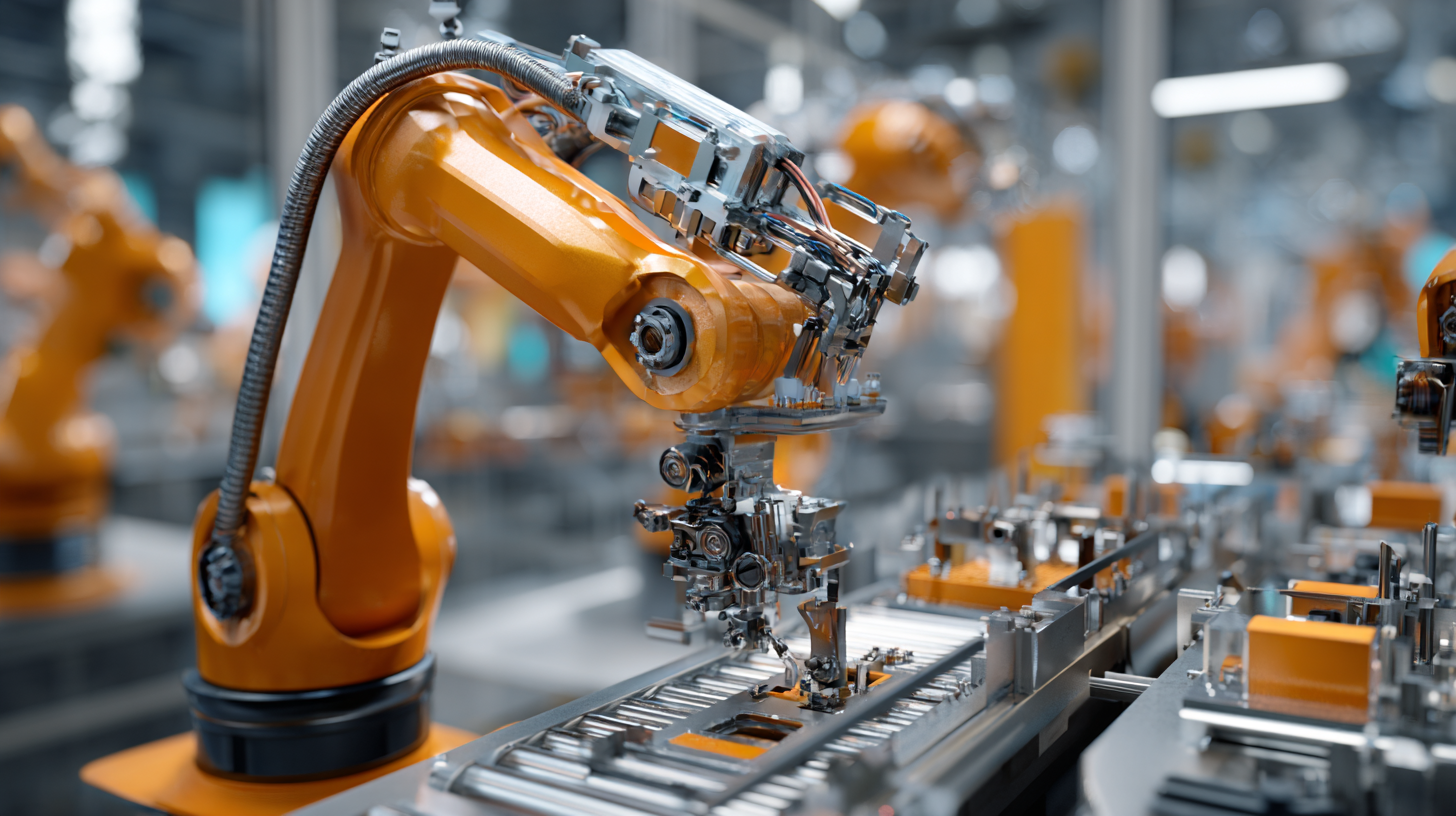

In the rapidly evolving landscape of manufacturing, the integration of industrial robots has emerged as a pivotal strategy for enhancing operational efficiency and productivity. According to a recent report by the International Federation of Robotics, global industrial robot sales surged by 26% in 2021, reflecting a growing trend towards automation. Industrial robot integrators play a crucial role in this transformation, providing the expertise required to tailor robot systems to specific production needs.

By optimizing manufacturing lines, these integrators facilitate faster production cycles, reduce labor costs, and improve quality control, ultimately leading to significant competitive advantages. As manufacturers seek to adapt to the challenges of a post-pandemic world, the collaboration with industrial robot integrators becomes essential for unlocking the full potential of robotic automation and driving innovation across various sectors.

Industrial robot integrators play a pivotal role in enhancing production efficiency across various manufacturing sectors. By seamlessly implementing robotic systems, these integrators address the growing demand for precision and accuracy, particularly in fields like medical device manufacturing. As automation becomes integral to achieving higher production standards, the expertise of robot integrators ensures that manufacturers can scale their operations without compromising quality, even amidst budget constraints faced by small-to-mid-sized businesses.

Furthermore, the integration of advanced technologies—such as predictive maintenance and AI-driven analytics—allows manufacturers to not only streamline processes but also optimize their supply chains. This evolution is indicative of Industry 4.0's influence, where robotics and AI work in harmony to boost overall productivity. By leveraging these innovations, industrial robot integrators facilitate a transformative approach to manufacturing, enabling companies to adapt swiftly to market demands while achieving greater efficiency and output.

Industrial robot integrators play a pivotal role in modern manufacturing by implementing advanced technologies that enhance efficiency and productivity. Among these key technologies, artificial intelligence (AI) stands out for its ability to improve decision-making processes on the factory floor. By leveraging machine learning algorithms, integrators can analyze vast amounts of production data in real-time, enabling predictive maintenance and minimizing downtime. This intelligent approach not only optimizes workflow but also boosts the overall quality of manufacturing outputs.

Another critical technology employed by robot integrators is the Internet of Things (IoT). By connecting various machinery and devices within a manufacturing line, IoT facilitates seamless communication and data exchange. This interconnectedness ensures that all components operate harmoniously, allowing for real-time monitoring of production metrics. Furthermore, IoT integration assists in identifying bottlenecks and inefficiencies, providing managers with insights to make informed adjustments swiftly. As a result, manufacturing processes become more streamlined, reducing waste and enhancing throughput.

In the manufacturing realm, the integration of industrial robots has proven to be a game-changer. Case studies reveal that companies like Ford and Adidas have significantly enhanced their production efficiency through strategic robot integration. For instance, Ford's use of robotic arms in assembly lines has reduced manual labor and minimized human error, allowing for faster output and improved quality. Similarly, Adidas has adopted robot technology in their Speedfactory, which enables localized production and quicker response to market demands, demonstrating the versatility and adaptability of robot integration in manufacturing.

In the manufacturing realm, the integration of industrial robots has proven to be a game-changer. Case studies reveal that companies like Ford and Adidas have significantly enhanced their production efficiency through strategic robot integration. For instance, Ford's use of robotic arms in assembly lines has reduced manual labor and minimized human error, allowing for faster output and improved quality. Similarly, Adidas has adopted robot technology in their Speedfactory, which enables localized production and quicker response to market demands, demonstrating the versatility and adaptability of robot integration in manufacturing.

Tips: When considering robot integration, focus on a thorough assessment of your current production processes. Identify bottlenecks and areas where automation can yield tangible benefits. Collaborating with experts in robotic systems can also provide valuable insights into the specific technologies that best fit your operational needs.

Another successful example is Siemens, which implemented automated systems in their manufacturing plants to streamline logistics and assembly processes. By utilizing autonomous mobile robots, Siemens reduced material handling time, enhancing overall productivity. This illustrates that embracing robot technology not only improves efficiency but also transforms the manufacturing landscape towards Industry 4.0.

Tips: Start small by integrating robots into less complex tasks. This gradual approach allows for better management of the transition and can provide immediate returns on investment, paving the way for further automation in more demanding areas of production.

The role of industrial robot integrators has become increasingly vital in modern manufacturing environments, yet they face numerous challenges that can hinder the efficiency gains they seek to provide. One significant challenge is the rapid pace of technological advancement. With the introduction of new robotic systems and automation technologies, integrators must constantly update their skills and knowledge to implement the latest solutions effectively. This ongoing need for training can lead to operational delays and increased costs, as integrators juggle the integration of new technologies while maintaining existing systems.

Additionally, the complexity of integrating robots into diverse manufacturing processes poses another hurdle. Each production line is unique, often requiring tailored solutions that fit specific workflows and address particular challenges. Integrators must navigate varying levels of existing infrastructure and employee expertise, which can complicate the deployment of robotic systems. Furthermore, they face pressure from manufacturers to deliver results quickly while ensuring that the integration process does not disrupt production. Balancing these demands while meeting high standards of safety and performance is a significant challenge in today’s competitive manufacturing landscape.

| Dimension | Challenge | Impact on Efficiency | Proposed Solution |

|---|---|---|---|

| Technology Integration | Compatibility Issues | Delays in production | Standardization of components |

| Workforce Training | Skill Gaps | Increased downtime | Robust training programs |

| Customization | Tailoring Solutions | Longer lead times | Modular design approaches |

| Supply Chain Management | Material Shortages | Production halts | Diversify suppliers |

| Regulatory Compliance | Evolving Standards | Increased costs | Continuous monitoring systems |

The future of industrial robotics is poised to revolutionize manufacturing lines through advancements in automation and artificial intelligence. As manufacturers increasingly adopt collaborative robots—often called cobots—they can achieve greater flexibility and efficiency. These robots are designed to work alongside human operators, allowing for a more dynamic and responsive production environment. This integration not only enhances productivity but also reduces the risk of workplace injuries, as robots take on repetitive and physically demanding tasks.

Moreover, the rise of data-driven decision-making will further impact the landscape of manufacturing. With the integration of the Internet of Things (IoT) and machine learning, industrial robots can gather and analyze data in real-time, providing insights that lead to improved operational efficiency. Predictive maintenance powered by robotics can foresee potential equipment failures, ultimately minimizing downtime and cutting costs. Thus, the synergy between human intelligence and robotic precision is set to create more streamlined, adaptable, and efficient manufacturing lines in the years to come.