- sale@instructrobot.com

- Dallas, TX , United States

The rise of automation has transformed the landscape of manufacturing and logistics. Material handling robots are at the forefront of this change. According to recent industry reports, the material handling robots market was valued at $8 billion in 2022 and is projected to grow at a CAGR of 14% through 2030. This rapid growth highlights the increasing reliance on automation in everyday operations.

Choosing the right material handling robots requires careful consideration. Companies must assess their unique needs. Size, weight capacity, and task complexity are vital factors. Yet, many businesses rush this decision, overlooking essential details. A poor choice can lead to increased downtime and costs.

While the integration of material handling robots promises efficiency, it also poses challenges. Training staff and maintaining equipment are often underestimated. As you explore your options, reflect on these aspects. The right robot can dramatically enhance productivity. Nonetheless, being cautious and informed is crucial for success.

Material handling robots are transforming industries. They enhance productivity and reduce human error. In warehouses, these robots move heavy goods with precision. They operate tirelessly, leading to a safer and more efficient work environment. However, integrating these machines is not without challenges.

Choosing the right robot requires careful consideration. Look at load capacities and speed. Each industry has unique needs. A robot ideal for one task may falter in another. Adaptability is crucial. Training staff on how to work alongside robots is often neglected. This can lead to inefficiencies and frustration.

Some companies overlook maintenance needs. Neglected robots can lead to unexpected downtimes. Regular checks and updates are necessary. Without this, production can halt suddenly. Balancing automation with human skills is essential. Strive for collaboration, not replacement. Finding the right synergy can lead to seamless operations. Investing time in understanding these dynamics pays off.

| Tip Number | Tip | Key Consideration | Typical Applications |

|---|---|---|---|

| 1 | Assess Load Types | Consider weight, dimensions, and fragility | Packaging, Warehousing |

| 2 | Evaluate Space Constraints | Ensure robot can operate within facility layout | Manufacturing, Distribution |

| 3 | Determine Automation Level | Decide between fully automated vs. semi-automated | Order Fulfillment, Sorting |

| 4 | Compatibility with Existing Systems | Ensure integration with WMS or ERP | Inventory Management |

| 5 | Consider Safety Features | Look for sensors, emergency stops | Warehouse, Factory Floor |

| 6 | Assess Payload Capacity | Ensure robot can handle maximum load | Heavy Lifting, Shipping |

| 7 | Evaluate Maintenance Needs | Understand service frequency and costs | All Applications |

| 8 | Check Flexibility and Scalability | Can the robot adapt to changing needs? | E-commerce, Manufacturing |

| 9 | Review Robot's Range of Motion | Assess operational reach and agility | Assembly, Packaging |

| 10 | Analyze ROI and Total Cost of Ownership | Evaluate operational savings and expenses | All Industries |

When considering material handling robots, it’s important to assess your specific needs. Start by identifying the types of materials you will be handling. Different materials have unique requirements. For example, dealing with heavy pallets? You’ll need robots built to handle weight safely. On the other hand, if your materials are delicate, precision should be your priority.

Next, think about your workspace. Is it spacious or cramped? Some robots require more room to maneuver. Others might be compact but less versatile. Evaluate your layout and identify potential obstacles. A thorough assessment can help avoid costly mistakes later. Look for automation that fits smoothly into your processes. Sometimes, off-the-shelf solutions don’t align with specific requirements. Customization might be necessary, yet it can be complex and time-consuming.

Consider the range of tasks your robots will perform. Will they just transport goods or also sort them? Each function can impact the robot’s design and capabilities. Reflect on your long-term goals too. A solution that seems fitting today may not be adaptable to future changes. Flexibility should play a key role in your choice. Think beyond the immediate needs. Evaluate potential growth and changes in your operation.

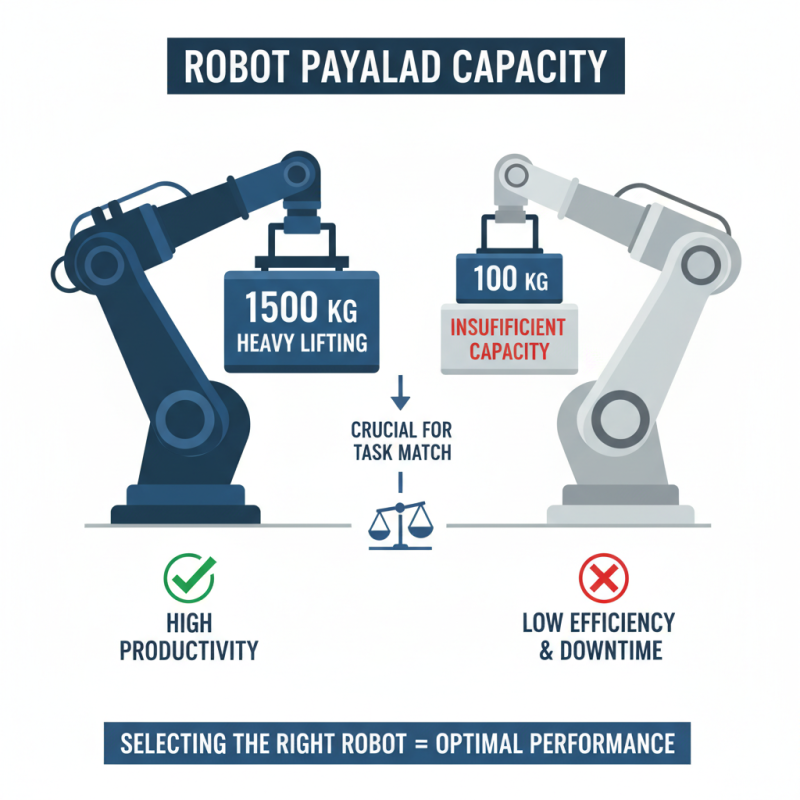

When evaluating robot performance specifications, it’s crucial to consider payload capacity. Some robots can handle weights as much as 1,500 kilograms, while others might only support 100 kilograms. This variance can significantly affect productivity. If a task requires heavy lifting, selecting a robot that falls short of capacity can lead to inefficiency and potential downtime.

Speed also plays a pivotal role in performance. According to a recent industry report, the fastest material handling robots operate at speeds exceeding 2 meters per second. Speed reductions might seem inconsequential, but they can severely impact throughput. Analyzing the specific applications and workflow is essential. Relying solely on speed can lead to overlooking other factors, like accuracy and precision.

Another critical area to assess is battery life and charging time. Robots with shorter battery lives may require frequent downtime, disrupting operations. Some reports indicate that inefficiencies can arise from robots needing to recharge every 4 hours in busy environments. Balancing performance features with operational needs is not easy. Each metric should align with your workflow requirements. This reflection on limitations is essential when choosing the right robot.

Choosing the right material handling robots can be challenging, especially with existing systems in mind. Integration is key. You need a cohesive strategy. Evaluate your current technology. Not every robot will fit seamlessly. Some may require additional adaptation. Know your limitations and possibilities.

Consider your operational flow. Analyze how robots will interact with existing machinery. A robot that complements your current setup can enhance productivity. Tips to consider include evaluating interface compatibility and data exchange capabilities. Also, explore how robots communicate with your software systems.

Remember, not all robots are designed for easy integration. Some may need extensive changes to your current environment. It’s vital to assess the costs involved. Sometimes, adapting robots can prove impractical. Focus on solutions that enhance efficiency without complicating operations. Make informed decisions that align with future growth and flexibility.

When investing in material handling robots, budgeting and cost analysis play crucial roles. Start by evaluating both direct and indirect costs.

Direct costs include the initial purchase price, installation fees, and necessary equipment upgrades.

Indirect costs stem from maintenance, training, and possible downtime. Each factor affects the overall financial impact on your operation.

Consider future needs and scalability before finalizing your budget. It can be tempting to choose the least expensive option, but hidden costs can arise later. What seems affordable may not suit your long-term goals.

Analyze your workflow and productivity gains. Are you maximizing efficiency with your investment? Regularly reviewing costs ensures improvements and aligns with budgetary constraints.

Another aspect to consider is financing options. Leasing versus purchasing can significantly impact cash flow. Short-term benefits may outweigh long-term costs in some scenarios.

Make decisions carefully. Sometimes, a lack of foresight leads to unforeseen expenses. It’s essential to balance the initial savings against potential operational setbacks. Your analysis should incorporate a comprehensive view of expenses, not just upfront costs.