- sale@instructrobot.com

- Dallas, TX , United States

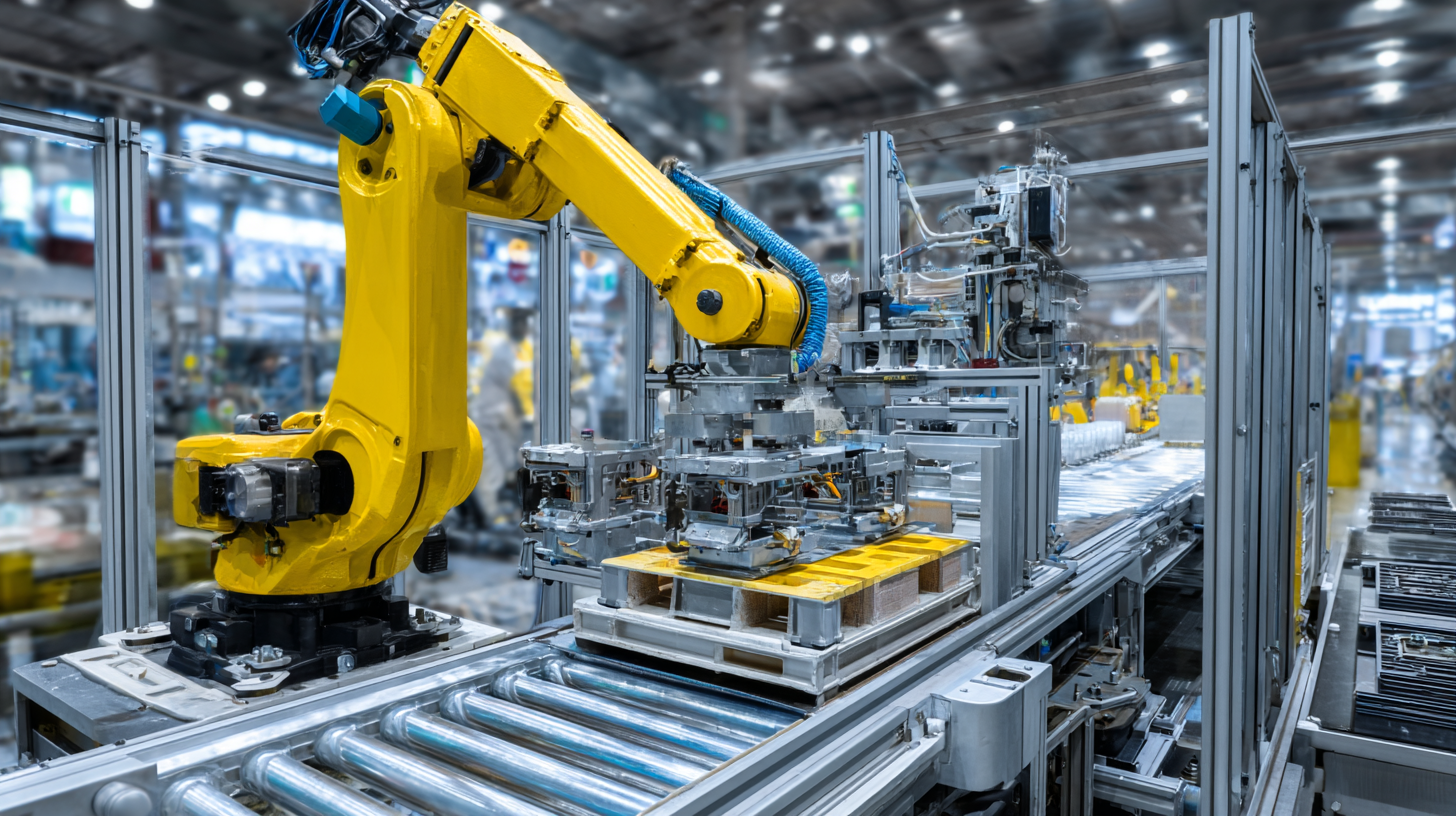

The rapid evolution of automation in manufacturing has led to significant advancements in efficiency, particularly through the implementation of industrial palletizing robots. According to a report by the International Federation of Robotics, the global market for industrial robots is projected to reach $70 billion by 2025, with palletizing applications accounting for a substantial share of this growth. The integration of industrial palletizing robots not only enhances the speed and accuracy of product handling but also reduces labor costs and minimizes the risk of workplace injuries. Furthermore, a study by McKinsey & Company indicates that automation could increase productivity by up to 25% in certain sectors. As industries strive for operational excellence and flexibility in production lines, the role of industrial palletizing robots becomes increasingly pivotal in shaping the future landscape of automated manufacturing environments.

The rise of industrial palletizing robots in modern manufacturing environments is transforming the landscape of production and logistics. According to a report by MarketsandMarkets, the global industrial robotics market is projected to reach $75.2 billion by 2025, with palletizing robots accounting for a significant portion of this growth. These robots not only enhance operational efficiency but also reduce labor costs and mitigate the risks of workplace injuries associated with manual palletizing processes.

In addition, the implementation of palletizing robots has been shown to improve precision and speed in product handling. A study conducted by the Association for Advancing Automation indicates that companies adopting robotic palletizing systems have reported efficiency gains of up to 30% compared to traditional methods. With advancements in AI and machine learning, these robots are becoming increasingly capable, allowing for the handling of a wider variety of products and configurations. This shift not only streamlines production workflows but also allows manufacturers to respond more rapidly to market demands, reinforcing the crucial role of automation in achieving competitive advantages in today's fast-paced manufacturing environment.

The integration of automation through industrial palletizing robots has revolutionized operations across various sectors, significantly enhancing efficiency. According to a recent report by MarketsandMarkets, the global industrial robotics market is projected to reach USD 75.6 billion by 2026, growing at a CAGR of 11.2%. This surge in investment underscores the industry's recognition of robotics as a critical driver of operational excellence. Palletizing robots can perform tasks with precision and speed, reducing the cycle time and minimizing errors that often occur in manual processes.

One of the key benefits of implementing robotics for palletizing operations is the substantial improvement in labor efficiency. A study by the Robotics Industries Association indicated that companies adopting robotic systems for palletizing can achieve productivity increases of up to 50%. Additionally, these robots can operate in challenging environments and maintain high performance levels, leading to a reduction in labor costs and enhanced workplace safety. As supply chains evolve, the need for flexible and scalable solutions becomes paramount, and palletizing robots are proving to be a valuable asset for manufacturers aiming to stay competitive in the market.

The rise of automation in supply chain processes, particularly through industrial palletizing robots, is transforming operational efficiency across various sectors. According to a report from McKinsey, companies that have effectively implemented automation strategies can improve productivity by up to 20-30%. Automation streamlines workflows by reducing the manual labor involved in palletizing, thereby minimizing errors and enhancing speed. For instance, a study by the National Institute of Standards and Technology (NIST) showed that automated systems could decrease labor costs by 40% while also increasing throughput.

To maximize the benefits of implementing palletizing robots, consider the following tips:

As supply chains become increasingly complex, leveraging automation can lead to significant competitive advantages. Research indicates that businesses utilizing robotic automation have a 71% higher productivity rate compared to traditional methods. By consistently integrating automation, companies can not only enhance their operational efficiency but also position themselves for growth in a rapidly evolving market.

The future of automation, particularly in the realm of industrial palletizing robots, is set to transform efficiency within supply chains dramatically. Innovations in this sector are paving the way for enhanced productivity, with the global market for AI robots predicted to reach a considerable $52.3 billion by 2024. Furthermore, the palletizer market is expected to grow from an estimated $758.17 million in 2023 to $1.15333 billion by 2031, showcasing a promising Compound Annual Growth Rate (CAGR) of 4.77%.

As industries increasingly adopt smart technologies, advancements such as the high-density sorting platform Matrix 8 are revolutionizing logistics processes. By optimizing the workflow of pallets and boxes, this cutting-edge solution highlights how technology can streamline operations.

Tip: Integrating innovative palletizing solutions can not only maximize space utilization but also significantly reduce labor costs. As we embrace these advancements, it becomes essential for businesses to invest strategically in automation technologies to remain competitive in the evolving market landscape. Embracing these technologies early can lead to substantial long-term benefits and operational efficiency.

As businesses consider the adoption of industrial palletizing robots, several challenges and considerations come into play. One significant hurdle is the initial investment cost. While the long-term savings and efficiency gains can be substantial, the upfront expenditure on robotics technology, along with the necessary infrastructure modifications, may be daunting for small to medium-sized enterprises. Companies must conduct thorough cost-benefit analyses to justify these expenses and ensure a positive return on investment.

Additionally, the integration of robotic systems into existing workflows poses logistical challenges. Employees may need retraining to work alongside robots effectively, which can disrupt daily operations. Moreover, businesses must consider the maintenance and technical support required to keep these systems running smoothly. Adapting to a new technological landscape demands not only financial resources but also a cultural shift within the organization to embrace automation. Addressing these challenges is crucial for companies to fully leverage the potential benefits of palletizing robots, ultimately enhancing operational efficiency.