- sale@instructrobot.com

- Dallas, TX , United States

As industries rapidly evolve in the face of technological advancements, the role of robotic equipment has become increasingly pivotal in shaping future operations. According to a report by the International Federation of Robotics, the global market for robotic systems is expected to reach $75 billion by 2025, driven by innovations in artificial intelligence, machine learning, and automation technologies.

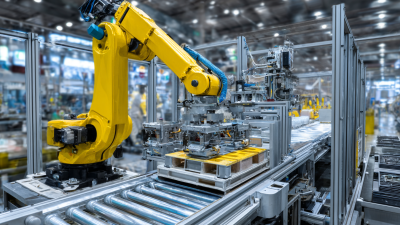

These advancements are not only streamlining production processes but also enhancing safety and precision across various sectors, including manufacturing, logistics, and healthcare. The integration of robotics in industry is projected to boost productivity by up to 40%, fundamentally transforming operational dynamics. This exploration of robotic equipment reveals a landscape ripe with opportunities, underscoring how companies can leverage these innovations to remain competitive in an increasingly automated world.

The integration of robotics in modern industries has transitioned from experimental stages to becoming a cornerstone of operational efficiency. According to a report by the International Federation of Robotics (IFR), the global stock of operational industrial robots reached an impressive 3 million units in 2021, reflecting a robust annual growth rate of 8%. This growth highlights the increasing reliance on robotic systems across various sectors, including manufacturing, logistics, and healthcare. Industries are leveraging robotics not only to enhance productivity but also to tackle labor shortages and improve workplace safety.

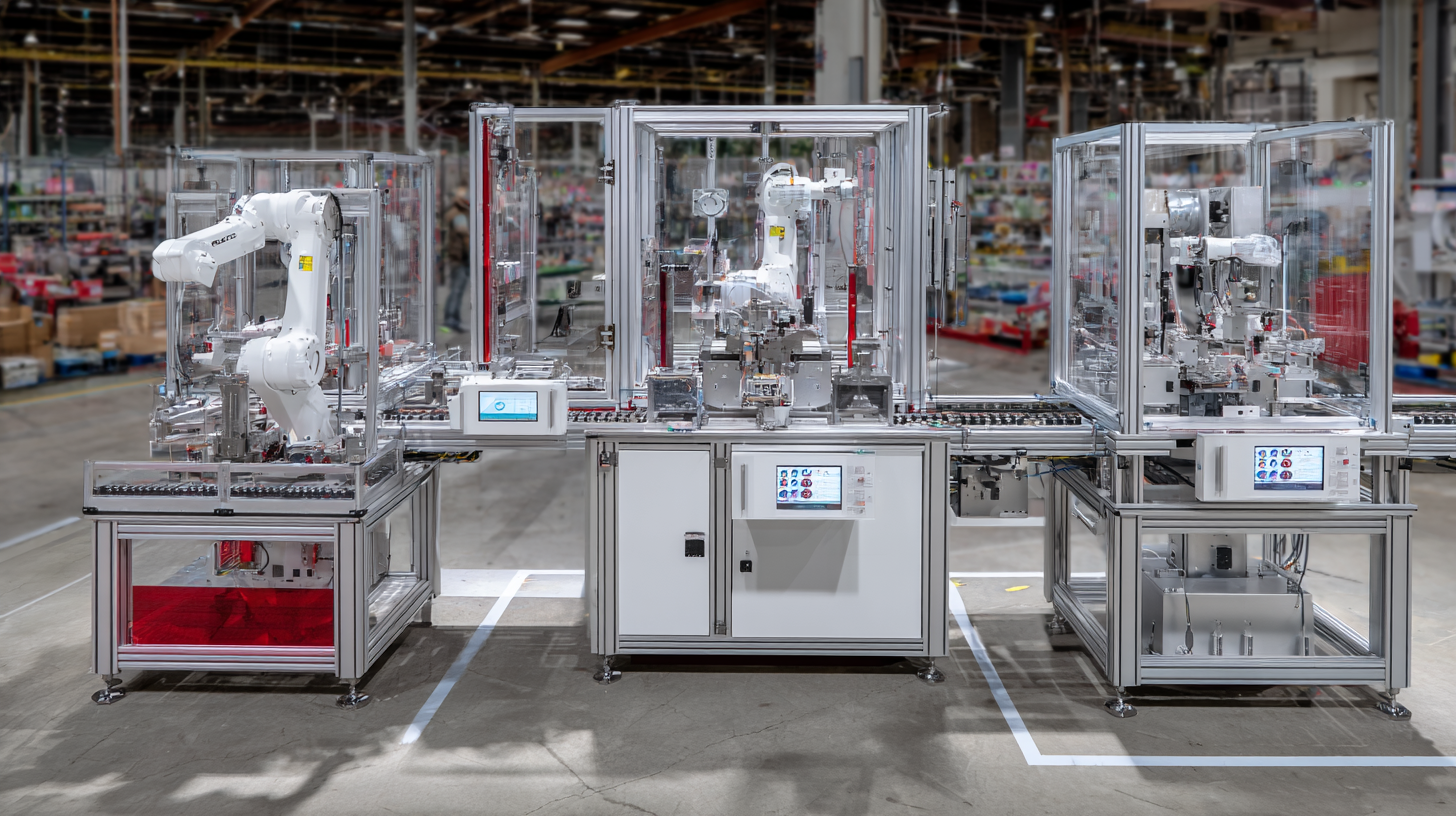

In particular, the manufacturing sector has witnessed significant advancements through automation. A study by McKinsey estimates that automation could lift productivity in manufacturing by 20-25% by 2030. Collaborative robots, or cobots, have gained popularity for their ability to work alongside human workers, facilitating complex tasks without compromising safety. Moreover, the logistics industry has seen innovations such as autonomous delivery drones and automated warehousing systems, drastically improving supply chain efficiency. As industries continue to embrace robotic solutions, the potential for enhanced precision, increased output, and reduced operational costs positions robotics as a pivotal element in shaping the future of modern industry applications.

The landscape of robotic technologies is evolving at a rapid pace, with several key innovations poised to redefine future industries. According to a report by the International Federation of Robotics (IFR), the global industrial robot market is expected to grow at a compound annual growth rate (CAGR) of 12% from 2021 to 2024, driven by advancements in automation and AI integration. This growth is exemplified by collaborative robots, or cobots, which are designed to work alongside humans. The increased flexibility and safety features of cobots are particularly appealing to small and medium-sized enterprises, allowing for optimized production without significant upfront investment.

Furthermore, the emergence of advanced machine learning algorithms is transforming the capabilities of robotic systems across various sectors. A study by McKinsey & Company indicates that the use of artificial intelligence within robotics could boost productivity by up to 40% in manufacturing industries by 2030. This substantial increase highlights the importance of integrating intelligent systems that can learn and adapt in real-time. As industries increasingly embrace these innovations, the potential for robotics to enhance operational efficiency, safety, and scalability appears limitless, shaping a new era of productivity across multiple domains.

As industries increasingly embrace advanced automation, the integration of robotic equipment has become paramount for enhancing operational efficiency. According to a report by McKinsey & Company, automation can increase productivity by up to 40% in certain sectors, illustrating the potential for significant economic impact. Successful integration strategies involve aligning robotic systems with existing workflows, ensuring that technology complements human skills rather than replacing them. This symbiotic relationship enables companies to not only improve efficiency but also boost employee satisfaction, as workers are freed from mundane tasks and are able to focus on higher-value activities.

Furthermore, a study by PwC highlights that organizations implementing automation can achieve a return on investment of approximately 15-25% within three years. To capitalize on these benefits, businesses must prioritize training and change management to ease the transition to automation. By investing in workforce development alongside technological advancements, companies can create a culture of innovation that adapts to the rapid changes within the industrial landscape. As industries move towards a more automated future, these strategies will be essential for organizations aiming to remain competitive in a rapidly evolving marketplace.

The integration of artificial intelligence (AI) and machine learning (ML) into robotics is poised to revolutionize various industries, driving innovation and efficiency in ways previously unimaginable. Recent findings suggest that AI has become a pivotal force behind emerging technologies, significantly influencing sectors such as healthcare and aerospace. According to a McKinsey Global Survey, over 50% of businesses reported adopting AI-related technologies in the last five years, underscoring an increasing reliance on these systems to enhance productivity and operational effectiveness.

In industrial settings, the concept of the AI-powered industrial metaverse is gaining traction, with virtual training environments enabling robots to learn more rapidly and adapt to diverse tasks. This shift not only reduces downtime but also fosters a more agile workforce that can respond quickly to market changes and demands. A report forecasting the AI robots market highlights continued growth, predicting substantial advancements driven by innovations in AI algorithms and robotics, with a market value expected to soar over the next decade, despite external factors like tariffs.

Furthermore, ethical considerations are becoming paramount as we advance towards artificial general intelligence (AGI). The research emphasizes the necessity of aligning AGI development with societal, technological, and ethical standards, ensuring that the benefits of AI in robotics are equitably distributed. Emphasizing responsible innovation will be key to harnessing AI’s full potential while mitigating risks associated with its integration into everyday applications.

The future of robotic equipment promises significant transformations across various industries, particularly in manufacturing. According to a report by McKinsey, the global AI market is projected to experience remarkable growth, escalating from $294.16 billion in 2025 to an impressive $1,771.66 billion by 2032, reflecting a robust compound annual growth rate (CAGR). This rapid expansion highlights the increasing reliance on AI-driven solutions in industrial processes, paving the way for smarter manufacturing techniques.

Moreover, the smart robotics market is poised for substantial growth, with estimates suggesting an increase from $15.65 billion in 2025 to around $96.75 billion by 2033, marking a staggering CAGR of 25.57%. This growth is significantly influenced by innovations in digital twin technology and enhanced simulation designs that are revolutionizing the manufacturing landscape. As industries adopt these advanced technologies, the ability to optimize production processes and improve product quality will become paramount, fundamentally reshaping the future industry paradigm by 2032.