- sale@instructrobot.com

- Dallas, TX , United States

As we delve into the future landscape of industrial automation, the rise of used robots in 2025 presents a transformative opportunity for various sectors. Experts suggest that the integration of these pre-owned robotic systems will not only drive cost efficiencies but also enhance operational capabilities. According to Dr. Emily Carter, a renowned robotics analyst, "The deployment of used robots represents a pivotal shift in how industries will approach automation, allowing businesses to scale their operations without the prohibitive costs typically associated with new technology."

In the coming years, the utilization of used robots is set to reshape manufacturing, logistics, and even healthcare industries. As companies increasingly turn toward sustainable practices, embracing the potential of pre-owned robotics offers a compelling solution. These systems are often equipped with advanced features that can meet the demands of modern production lines while remaining accessible to businesses of all sizes. By exploring the implications of this trend, we can better understand how used robots will act as catalysts for innovation and efficiency across diverse sectors.

Navigating this shift requires not only an awareness of the technology itself but also a strategic approach to integration and workforce adaptation. The dialogue surrounding used robots will undoubtedly evolve, enlightening stakeholders on best practices and potential hurdles. As we embark on this exploration, it is crucial to consider how these robotic systems can redefine operational paradigms and drive industry growth in the near future.

As industries continue to evolve, the market for second-hand robots is experiencing significant growth. By 2025, many companies are expected to embrace bought-back technology, capitalizing on the cost-effectiveness and efficiency of used robots. This trend is driven by the high demand for automation across various sectors, including manufacturing, logistics, and healthcare. Businesses are increasingly recognizing the value of integrating pre-owned robots, as they offer a lower barrier to entry for automation while still delivering reliable performance.

Key trends shaping the second-hand robot market include the development of refurbishment technologies and enhanced warranty services. Companies specializing in robotic refurbishment are emerging, focusing on extending the lifespan of used robots through upgrades and repairs. Additionally, more manufacturers are providing incentives for businesses to trade in their older models, facilitating a smoother transition to second-hand options. These advancements not only benefit consumers by reducing costs but also promote sustainability within the industry, as refurbished robots require fewer resources than new ones. As the market matures, we anticipate seeing a broader range of robots available for various applications, transforming how industries operate.

As industries increasingly focus on automation and efficiency, the rise of used robots presents a compelling opportunity for businesses in 2025. Purchasing used robots can significantly reduce initial investment costs, allowing companies to allocate resources toward other critical areas, such as training and technology integration. This cost-saving approach can enhance overall productivity, enabling businesses to remain competitive in a rapidly evolving market.

Moreover, the integration of used robots into existing workflows can drive long-term savings beyond the purchase price. With advanced AI capabilities, these robots can handle tasks with precision and speed, ultimately leading to reduced operational costs and improved service delivery. As companies evaluate the financial implications, the shift toward used robots could very well redefine industry standards, fostering a culture of innovation while minimizing financial risk. By capitalizing on the benefits of used robotics, businesses can position themselves as leaders in their respective markets, embracing the future of automated solutions.

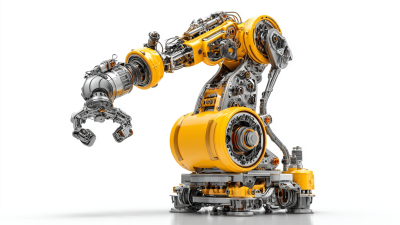

The rise of used robots in manufacturing is set to dramatically enhance operational efficiency by 2025. With the industrial robotics market projected to surge from USD 55.1 billion to an estimated USD 291.1 billion by 2035, the cost-effectiveness of adopting used robots is appealing to many manufacturers looking to optimize production without the hefty price tag of new machinery. These robots often come equipped with advanced functionalities, making them suitable for a variety of tasks, such as assembly and logistics, thereby streamlining operations across facilities.

Moreover, the integration of collaborative robots (cobots) is transforming the landscape of flexible manufacturing. By implementing adaptive automation and artificial intelligence, manufacturers can create dynamic workflows that significantly enhance productivity. This technological evolution is particularly evident in industries like beverage production, where efficiency, quality, and sustainability are paramount. The utilization of used robots not only helps in reducing the operational costs but also allows companies to rapidly adapt to changing market demands while ensuring high throughput in their production processes.

| Industry | Percentage of Used Robots Utilized (%) | Projected Increase in Efficiency (%) | Cost Savings (Million USD) |

|---|---|---|---|

| Automotive | 65 | 20 | 300 |

| Electronics | 70 | 25 | 150 |

| Food & Beverage | 60 | 15 | 75 |

| Pharmaceuticals | 55 | 18 | 90 |

| Textiles | 50 | 12 | 40 |

As industries increasingly embrace automation, integrating used robots into the existing workforce will become a vital strategy for companies aiming to enhance efficiency while managing costs. The first step in this integration process is to assess the specific needs of the workforce and identify tasks that can be automated with pre-owned robotic solutions. Organizations should focus on aligning the capabilities of acquired robots with the skills of human workers, ensuring that both can complement each other’s strengths.

Training and upskilling employees to work alongside these robots is equally important. Businesses should invest in training programs that not only educate workers on how to operate and maintain the used robots but also encourage collaboration between humans and machines. This approach fosters a culture of innovation and adaptability, empowering the workforce to embrace technological advancements rather than fear them. By effectively integrating used robots, companies can optimize productivity, reduce operational risks, and foster a positive work environment that thrives on teamwork and continuous improvement.

The rising trend of adopting used robots in various industries by 2025 presents significant environmental implications. As businesses increasingly turn to pre-owned robots to enhance productivity while minimizing costs, the demand for these machines is expected to surge. This shift not only contributes to reducing the carbon footprint associated with manufacturing new robots but also extends the lifecycle of existing technology. By reusing rather than discarding robotic equipment, industries can substantially cut down on electronic waste, which is a growing global concern.

Moreover, the emphasis on sustainability through the use of previously owned robots aligns with global efforts to combat climate change. Companies that embrace a circular economy approach are likely to find that their operational strategies not only benefit their bottom lines but also contribute positively to environmental health. As these machines often come with improved energy efficiency and reduced resource consumption, their integration into supply chains could redefine operational norms, making it possible for industries to meet stricter environmental regulations while pursuing innovative growth.