- sale@instructrobot.com

- Dallas, TX , United States

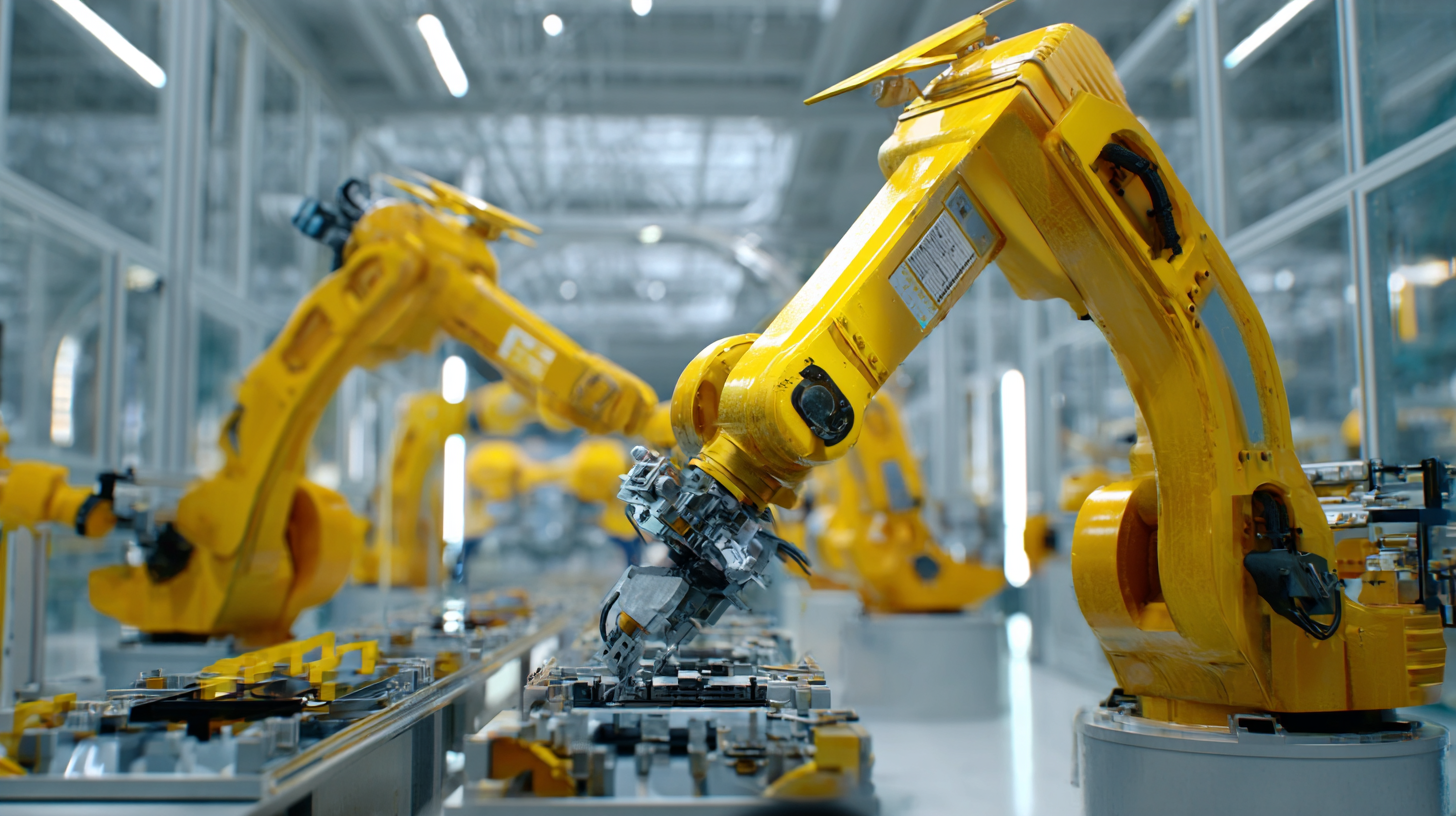

In the rapidly evolving landscape of manufacturing, the integration of technology has become paramount in enhancing efficiency and productivity. Among the frontrunners in this technological revolution are Fanuc industrial robots, which have transformed traditional manufacturing processes. These advanced robotic systems not only automate repetitive tasks but also optimize workflows and reduce human error, leading to significant improvements in production rates.

The ability of Fanuc industrial robots to work alongside human operators in a collaborative manner further heightens their impact, facilitating a seamless blend of human intelligence and robotic precision. As industries strive to remain competitive in a global market, understanding the multifaceted benefits that Fanuc industrial robots bring to operational efficiency is essential.

This article will explore various tips and strategies to harness the power of Fanuc industrial robots, ultimately paving the way for enhanced manufacturing outcomes and a more productive future.

In today’s fast-paced manufacturing environments, the integration of Fanuc industrial robots has become a pivotal element in enhancing efficiency and productivity. These robots not only streamline operations but also bring a level of precision that is hard to achieve with human labor alone. By automating repetitive and hazardous tasks, Fanuc robots allow human workers to focus on more complex activities, thus optimizing resource allocation across the factory floor.

**Tip:** When considering the implementation of Fanuc robots, assess your specific operational needs and workflows. Customizing robot programming to fit unique production lines can yield significant improvements in performance.

As the manufacturing landscape continues to evolve, the role of Fanuc industrial robots expands. Their adaptive learning capabilities ensure they stay relevant in varying production scenarios, facilitating quick changes in manufacturing strategies. This adaptability makes them invaluable during market fluctuations or shifts in consumer demand.

**Tip:** Invest time in training your team on robot operation and maintenance. A well-trained workforce not only enhances productivity but also maximizes the lifespan and effectiveness of robotic systems, ensuring a higher return on investment.

The integration of robotic automation into manufacturing processes has revolutionized production efficiency. Fanuc industrial robots, known for their precision and reliability, exemplify how automation can streamline operations. By performing repetitive tasks with speed and accuracy, these robots significantly reduce cycle times and minimize human error, leading to an overall increase in throughput. With the ability to operate continuously without fatigue, they ensure that production lines maintain a consistent output, which is crucial in meeting market demands.

Moreover, the implementation of Fanuc robots facilitates flexibility in manufacturing environments. These robots can be easily programmed and reconfigured for different tasks, allowing manufacturers to adapt quickly to changes in product design or production volume. This adaptability not only enhances operational efficiency but also leads to better resource management, as companies can allocate labor more effectively. As a result, organizations can achieve higher productivity levels, ultimately contributing to improved profitability and competitive advantage in the marketplace.

In assessing the productivity gains provided by Fanuc industrial robots, several key performance indicators (KPIs) emerge as critical for manufacturers. One primary KPI is cycle time reduction, which measures the time required to complete a manufacturing process. By integrating Fanuc robots, companies often witness a significant decrease in cycle times due to the robots' precision and ability to operate continuously without fatigue. This enables manufacturers to increase output while maintaining high-quality standards.

Another vital KPI is overall equipment effectiveness (OEE), which evaluates the efficiency of manufacturing processes. OEE accounts for availability, performance, and quality, providing a comprehensive view of how effectively equipment is utilized. When Fanuc robots are deployed, manufacturers frequently experience improved OEE scores as these robots enhance productivity by minimizing downtime, optimizing throughput, and ensuring consistent product quality. Additionally, the flexibility of Fanuc robots allows for quick reprogramming and adaptation to different tasks, further contributing to efficiency improvements and the ability to meet fluctuating market demands.

| Metric | Before Implementation | After Implementation | Percentage Improvement (%) |

|---|---|---|---|

| Production Output (units/hour) | 100 | 150 | 50% |

| Downtime (hours/week) | 10 | 4 | 60% |

| Labor Costs ($/week) | 5000 | 3500 | 30% |

| Product Defect Rate (%) | 5 | 2 | 60% |

| Energy Consumption (kWh/week) | 2000 | 1500 | 25% |

Fanuc industrial robots have made significant strides in enhancing manufacturing efficiency across various industries. For instance, a case study conducted by the A3 Robotics Industry Association reveals that companies implementing Fanuc robots in assembly operations have seen productivity increase by up to 30%. In the automotive sector, manufacturers using Fanuc robots for welding and painting have reported a reduction in cycle time by approximately 25%, allowing them to meet high demand while maintaining quality standards.

Similarly, in the electronics industry, Fanuc robots play a crucial role in handling delicate components. According to a report from the International Federation of Robotics, companies integrating these robots into their production lines experience a decrease in errors and rework rates by around 40%. Furthermore, the flexibility of Fanuc robots allows for quick changes between product lines, which is essential in the fast-paced electronics market where consumer preferences shift rapidly. These real-world applications highlight the transformative impact of Fanuc robots on manufacturing and illustrate their potential for driving significant improvements in efficiency and productivity.

This chart illustrates the improvement in manufacturing efficiency and productivity metrics across various industries after the implementation of Fanuc industrial robots. The data represents percentage increases observed in production lines with automation compared to traditional methods.

As the manufacturing landscape continues to evolve, the integration of robotics, particularly Fanuc industrial robots, plays a crucial role in enhancing efficiency and productivity. These machines are not only designed to automate repetitive tasks but are also becoming smarter and more adaptable to the diverse needs of modern factories. Future trends indicate a shift towards collaborative robots (cobots) that work alongside human operators, enhancing flexibility and safety in manufacturing environments.

Tip: When considering the implementation of robotics in your production line, it's essential to assess the specific tasks that could benefit from automation. Identify processes that are time-consuming and prone to human error, as these are often the best candidates for robotic assistance. This approach ensures that your investment yields the highest possible return.

Looking ahead, the evolution of robotics will likely focus on artificial intelligence and machine learning capabilities. Such advancements will allow robots to not only perform tasks with precision but also learn from their experiences, continuously improving their efficiency. As the technology advances, manufacturers must remain informed and adaptable to leverage these innovations effectively.

Tip: Stay updated on the latest technological trends in robotics by attending industry workshops and trade shows. Networking with other professionals can provide insights into best practices and emerging solutions that may benefit your manufacturing processes.