- sale@instructrobot.com

- Dallas, TX , United States

In today's rapidly evolving industrial landscape, the integration of technology into supply chain operations has never been more crucial. The rise of the **industrial palletizing robot** signifies a pivotal transformation in how goods are handled and distributed. According to a report by MarketsandMarkets, the global market for industrial robots in palletizing applications is projected to grow from $2.5 billion in 2020 to $4.8 billion by 2025, reflecting an impressive compound annual growth rate (CAGR) of 14.5%. This surge is driven by the increasing demand for automation to enhance efficiency, reduce labor costs, and improve workplace safety. As organizations strive to optimize their supply chains, adopting industrial palletizing robots emerges as a key strategy to streamline operations and meet the rising customer expectations for speed and accuracy. Through advanced technology and the ability to function in diverse environments, these robots are not only redefining logistics but also paving the way for a more efficient and resilient supply chain infrastructure.

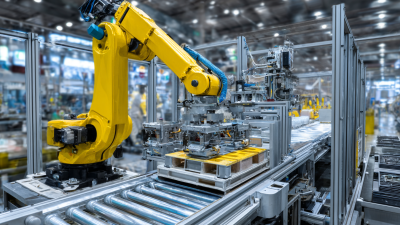

Industrial palletizing robots have become a cornerstone of modern supply chain efficiency, transforming how goods are handled and processed. These automated systems are designed to efficiently stack products onto pallets for storage or shipping. By employing advanced technologies such as vision systems and artificial intelligence, these robots can accurately identify and manipulate a variety of product shapes and sizes, streamlining operations in warehouses and manufacturing facilities.

The functionality of palletizing robots typically includes load analysis and optimal positioning, which helps enhance stability during transport. They can work continuously without breaks, significantly increasing throughput while reducing labor costs. Moreover, these robots can easily be programmed and reconfigured to handle different products, providing companies with the flexibility needed to adapt to market changes. As industries seek to improve their logistics and reduce errors, the implementation of industrial palletizing robots offers a promising solution to meet these demands efficiently.

Modern palletizing robots are at the forefront of revolutionizing supply chain efficiency, equipped with advanced technologies that enhance operational effectiveness. One key feature is their ability to adapt to various product sizes and weights, making them versatile for different industries. According to a report from the International Federation of Robotics, the use of industrial robots, including palletizers, has grown by 12% annually over the past decade, reflecting a significant shift towards automation in manufacturing and logistics.

Another critical aspect is the integration of artificial intelligence (AI) and machine learning within these robots, enabling them to optimize stacking patterns and improve throughput. A study by McKinsey indicates that automating the palletizing process can reduce labor costs by up to 30% and increase speed by about 25%, leading to enhanced overall productivity. Furthermore, modern palletizing robots come with advanced vision systems, allowing them to accurately identify and handle a wide range of products, which further streamlines warehouse operations and minimizes errors during the shipping process. As industries continue to embrace these innovations, the enhanced efficiency brought by modern palletizing robots will undoubtedly reshape the supply chain landscape.

Palletizing robots represent a significant advancement in supply chain systems, seamlessly integrating with various operations to enhance efficiency. These robots automate the process of stacking and organizing products onto pallets, which minimizes the need for manual labor and reduces the risk of injuries associated with repetitive tasks. By utilizing advanced sensors, machine learning algorithms, and computer vision, palletizing robots can adapt to different product shapes and sizes, allowing for more fluid integration into existing workflows.

Furthermore, the integration of palletizing robots with supply chain systems offers real-time data exchange and process optimization. Modern robotic systems communicate directly with inventory management software, providing accurate updates on stock levels and ensuring that palletizing processes align with demand. This synergy not only streamlines operations but also enhances accuracy in order fulfillment, ultimately leading to reduced lead times and improved customer satisfaction. As businesses continue to embrace automation, the role of palletizing robots in supply chain efficiency will become increasingly critical.

| Dimension | Data |

|---|---|

| Average Cycle Time Reduction | 30% less |

| Increase in Throughput | 25% more packages/hour |

| Labor Cost Savings | 15% reduction |

| Error Rate Decrease | 40% less |

| Space Utilization | 20% more efficient |

| Implementation Time | 3 to 6 months |

The integration of industrial palletizing robots into supply chains has proven to be a game-changer in reducing labor costs while significantly enhancing productivity. By automating the repetitive and physically demanding tasks of palletizing, companies can streamline their operations and reduce their dependence on manual labor. This shift not only lowers wage expenses but also mitigates associated costs such as worker benefits and training. As robotic technology continues to advance, businesses are increasingly able to reallocate their human workforce to more value-added roles, leading to a more skilled labor force.

Moreover, the productivity gains from implementing palletizing robots are substantial. These machines can operate at a speed and precision that far surpasses human capabilities, handling a higher volume of goods with minimal errors. This efficiency translates into faster turnaround times in warehouses and manufacturing facilities, enabling companies to respond swiftly to market demands. With robotics taking over labor-intensive tasks, businesses can achieve higher throughput without compromising quality, ultimately leading to improved overall performance in the supply chain. As a result, companies are finding themselves more competitive in an increasingly demanding marketplace.

The industrial palletizing robot market is set for remarkable growth, projected to expand from an estimated value of $758.17 million to approximately $1.15333 billion by 2031, reflecting a compound annual growth rate (CAGR) of 4.77%. This growth is indicative of the transformation occurring within supply chains as businesses increasingly incorporate automation technologies to enhance their operational efficiency. The integration of palletizing robots not only streamlines the stacking process but also mitigates human error, thereby ensuring more consistent and reliable outputs.

As companies strive to keep pace with evolving demands, future trends in palletizing technology are anticipated to include advancements in artificial intelligence and machine learning. These technologies will facilitate the development of smarter robots capable of adapting to various product types and packaging configurations, significantly improving flexibility within the supply chain. Furthermore, the rise of returnable transport packaging (RTP), projected to grow from $25.25 billion in 2025 to $35 billion by 2033, underscores a collective shift towards sustainability and cost-efficiency, aligning with modern supply chain strategies focused on minimizing environmental impact while maximizing productivity.