- sale@instructrobot.com

- Dallas, TX , United States

In the rapidly evolving landscape of manufacturing and automation, industrial robotic systems have emerged as a game-changer in 2023. As companies strive to enhance productivity, reduce operational costs, and maintain competitive advantages, the integration of advanced robotic technologies has become essential. From assembly lines to quality control, these systems are not only increasing efficiency but also redefining the roles of human workers in the industrial sector.

This article delves into the top 10 industrial robotic systems that are leading the charge in revolutionizing automation. By examining their capabilities, applications, and impact on various industries, we aim to provide insights into how these sophisticated machines are shaping the future of work. Whether it’s through collaborative robots (cobots) assisting human operators or autonomous robots streamlining logistics, the transformative power of industrial robotic systems is evident. As we explore these innovative technologies, we will highlight how they are not just tools, but integral components of smart factories that drive the next wave of industrial productivity.

In 2023, the landscape of industrial automation is being transformed by collaborative robots, or cobots, which are designed to work alongside human operators. These advanced machines are enhancing workforce efficiency by taking over repetitive and physically demanding tasks, allowing human employees to focus on more complex and value-added activities. This synergy between humans and cobots not only boosts productivity but also reduces the risk of workplace injuries, as these robots can handle heavy lifting and intricate operations without fatigue.

Leading manufacturers are investing heavily in the development of user-friendly cobots equipped with artificial intelligence and machine learning capabilities. These features enable the robots to adapt to various tasks and environments, ensuring that companies can implement automation tailored to their specific needs. As a result, businesses of all sizes are able to harness the potential of collaborative robots, fostering a more agile workforce while streamlining operations. The focus on enhancing workforce efficiency is evident, as companies are increasingly recognizing the positive impact of cobot integration on both production outcomes and employee satisfaction.

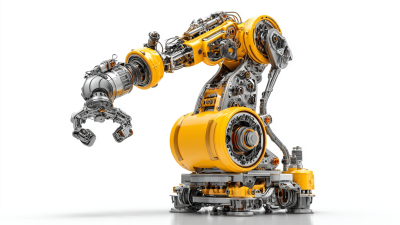

As we move through 2023, AI-powered robotic arms are becoming pivotal in redefining precision manufacturing. The integration of artificial intelligence in robotics is enhancing the accuracy and efficiency of production processes. This transformation is evident in industries that leverage advanced AI solutions to optimize operations, ensuring that products meet stringent quality standards while significantly reducing production time.

Moreover, the continual advancement in technologies like digital twins is enabling manufacturers to simulate and perfect their processes before implementation. Startups focusing on industrial AI and 3D simulations are paving the way for a new era of manufacturing innovation. The introduction of autonomous robots, like those being developed by leading companies, aims at streamlining workflows in warehouses and factories, showcasing the remarkable potential of AI to revolutionize industry standards. As factories become increasingly automated, precision and quality will reach unprecedented levels, setting new benchmarks for manufacturing excellence.

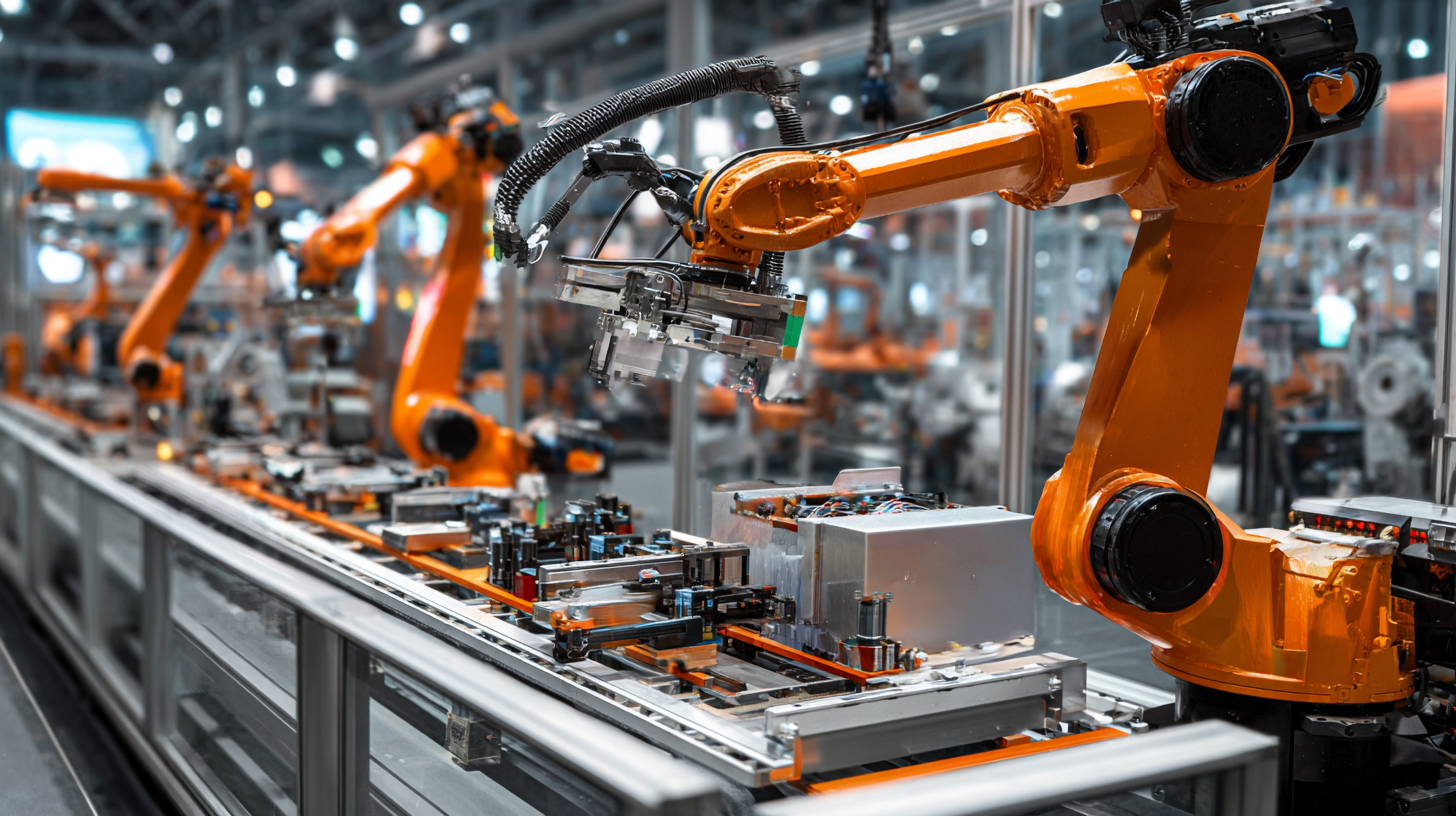

The evolution of next-gen automated mobile robots is significantly transforming warehouse logistics, streamlining operations and enhancing efficiency. According to a recent report by the International Federation of Robotics, the global market for logistics robots is projected to exceed $37 billion by 2025, driven by the increasing demand for automation in supply chain management. These advanced systems are capable of navigating complex environments, reducing reliance on human labor, and minimizing operational costs.

Automated mobile robots (AMRs) utilize sophisticated technologies such as LiDAR, machine learning, and computer vision to optimize warehouse processes. For instance, a study by McKinsey highlights that implementing AMRs can boost productivity by 20-30% in logistics operations. Major players like Amazon and Walmart are investing heavily in these technologies, with Amazon alone deploying over 200,000 robots in its fulfillment centers. This trend underscores how automated mobile robots are not only reshaping operational workflows but also setting new benchmarks for efficiency in the warehousing sector.

The landscape of industrial automation in 2023 is being significantly transformed by advanced vision systems, which enhance robotic perception and interaction. According to a recent report from the International Federation of Robotics (IFR), this technology has led to a 30% increase in operational efficiency across manufacturing sectors. These sophisticated vision systems enable robots to better perceive their environment, recognize objects, and adapt to dynamic settings, thus improving their ability to work alongside human operators. With advancements in machine learning and artificial intelligence, the synergy between robots and human workers is becoming more seamless.

As companies integrate these vision systems, embracing strategies that emphasize real-time data processing and camera technology is crucial. For instance, deploying 3D vision capabilities can provide robots with a more comprehensive understanding of spatial relationships. Tips for successful implementation include

Moreover, the continuous evolution of cameras and sensor technology, which are projected to grow at a CAGR of 15% according to Market Research Future, suggests that industries will be able to harness even more intelligent automation solutions. Understanding how to leverage these technologies will be key for businesses aiming to maintain a competitive edge in an increasingly automated world.

As we enter 2023, the push for sustainable manufacturing practices becomes increasingly critical, and innovative robotic solutions are at the forefront of this transformation. According to a recent report by the International Federation of Robotics, the global industrial robot market is expected to surge to $66 billion by 2027, driven by the demand for efficient and environmentally-friendly production methods. This rapid growth illustrates how technological advancements in robotics are helping companies reduce waste and improve energy efficiency, aligning with the goals of sustainable manufacturing.

Incorporating robotics into production can lead to significant reductions in carbon emissions. A study from McKinsey showed that automating processes with industrial robots could cut emissions by up to 20%. This is particularly important as manufacturers seek to comply with stricter regulations and societal pressures for greener operations. Utilizing robots for tasks such as material handling and assembly not only streamlines operations but also minimizes the environmental impact of traditional manufacturing methods.

**Tip:** When considering robotic solutions, prioritize systems that offer adaptability and connectivity. Integration with IoT devices can enhance the efficiency of your operations while providing real-time data to monitor and optimize energy use.

**Tip:** Examine the lifecycle of the robots themselves; choose models that are designed for easy repair and recycling. This not only contributes to lower operational costs but also aligns with a sustainable framework for manufacturing.

This chart illustrates the ten leading industrial robotic systems in 2023, highlighting their key capabilities in automation and sustainable manufacturing practices.