- sale@instructrobot.com

- Dallas, TX , United States

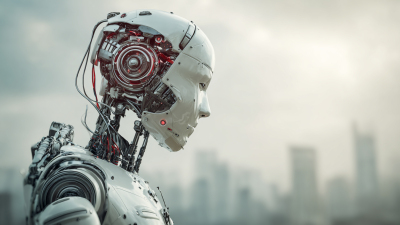

In the rapidly evolving landscape of technology, robotic equipment has emerged as a game-changer across various industries, transforming how businesses operate and enhancing efficiency. In 2023, innovation in robotics is at its peak, with groundbreaking advancements enabling organizations to streamline processes, reduce human error, and increase productivity. This surge in innovative robotic solutions not only addresses the challenges faced in traditional workflows but also paves the way for new opportunities in sectors such as manufacturing, healthcare, logistics, and beyond.

As we delve into the top 10 innovative robotic tools making waves in industries this year, we'll spotlight the "Top 5" that stand out due to their unique capabilities and practical applications. These robotic equipment marvels are not merely enhancements to existing systems; they represent a fundamental shift in operational paradigms, bringing about smarter, safer, and more efficient ways of working. From autonomous robots that navigate complex environments to advanced automation systems that optimize production lines, the impact of these technologies is profound and far-reaching. Join us as we explore the robotic advancements that are reshaping the future of industry in 2023.

In 2023, transformative robotics are reshaping the manufacturing landscape, driving efficiency and productivity to new heights. According to a recent report from the International Federation of Robotics (IFR), the adoption of advanced robotic systems in manufacturing has increased by 20% compared to the previous year. This surge is fueled by technologies such as AI and machine learning, enabling robots to perform complex tasks with precision and adaptability. For instance, collaborative robots, or cobots, are becoming essential in factories, working alongside human operators and enhancing their capabilities while maintaining safety and flexibility.

Additionally, the integration of robotics in supply chain operations has proven to be a game-changer. A study by McKinsey reveals that companies implementing robotic process automation (RPA) in their logistics processes can reduce operational costs by up to 30%. Robots equipped with vision systems and advanced algorithms can optimize inventory management and streamline warehousing operations, which is vital in an era where efficiency is paramount. The shift towards intelligent robotic systems not only enhances productivity but also helps manufacturers meet increasing consumer demands with greater agility and accuracy.

| Equipment Type | Main Function | Industry Application | Efficiency Improvement (%) |

|---|---|---|---|

| Collaborative Robots (Cobots) | Assisting human workers | Manufacturing | 30% |

| Autonomous Mobile Robots (AMRs) | Material transport | Warehouse | 25% |

| Robotic Process Automation (RPA) | Automating workflows | Finance | 40% |

| Drones | Aerial surveillance | Agriculture | 20% |

| Automated Guided Vehicles (AGVs) | Automated transport | Logistics | 35% |

| 3D Printing Robots | Additive manufacturing | Construction | 50% |

| Robotic Exoskeletons | Enhancing human strength | Healthcare | 15% |

| Robot-Assisted Surgery Systems | Precision surgery | Medical | 45% |

| Smart Inventory Robots | Inventory tracking | Retail | 30% |

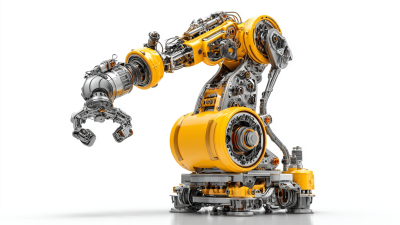

| Industrial Robotic Arms | Precision assembly | Manufacturing | 60% |

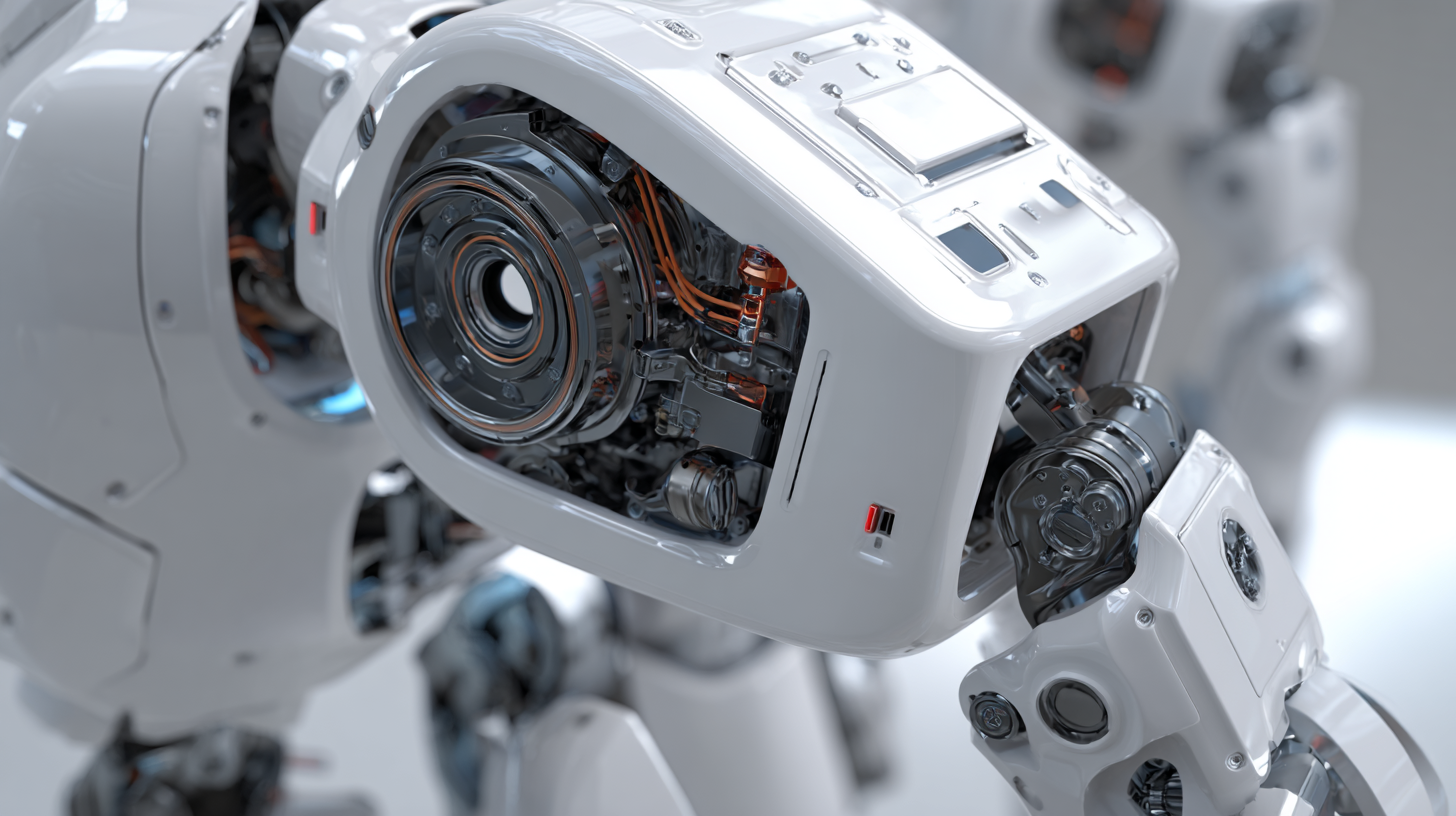

In 2023, AI-powered robots are at the forefront of transforming healthcare automation and patient care. With hospitals in China rapidly embracing AI technologies, patients can now interact with digital health assistants for interpreting medical checkups and managing health queries. This shift to automation is not only enhancing user experience but also freeing healthcare professionals from administrative burdens, allowing them to focus more on patient care.

The AI robots market is projected to reach an impressive USD 124.26 billion by 2034, reflecting a compelling shift in how healthcare services are being delivered. Collaborations between tech companies and hospitals are leading to the development of innovative medical robots that assist in surgeries, rehabilitation, and patient monitoring, highlighting the vast potential of these technologies in improving healthcare outcomes.

Tips: When considering the implementation of AI in healthcare, institutions should prioritize training staff to work alongside these technologies to maximize their benefits. Additionally, patient education on the use of AI tools can significantly enhance their acceptance and lead to better health management outcomes. It's also crucial to maintain a balance between automation and human touch to ensure that patient care remains compassionate and personalized.

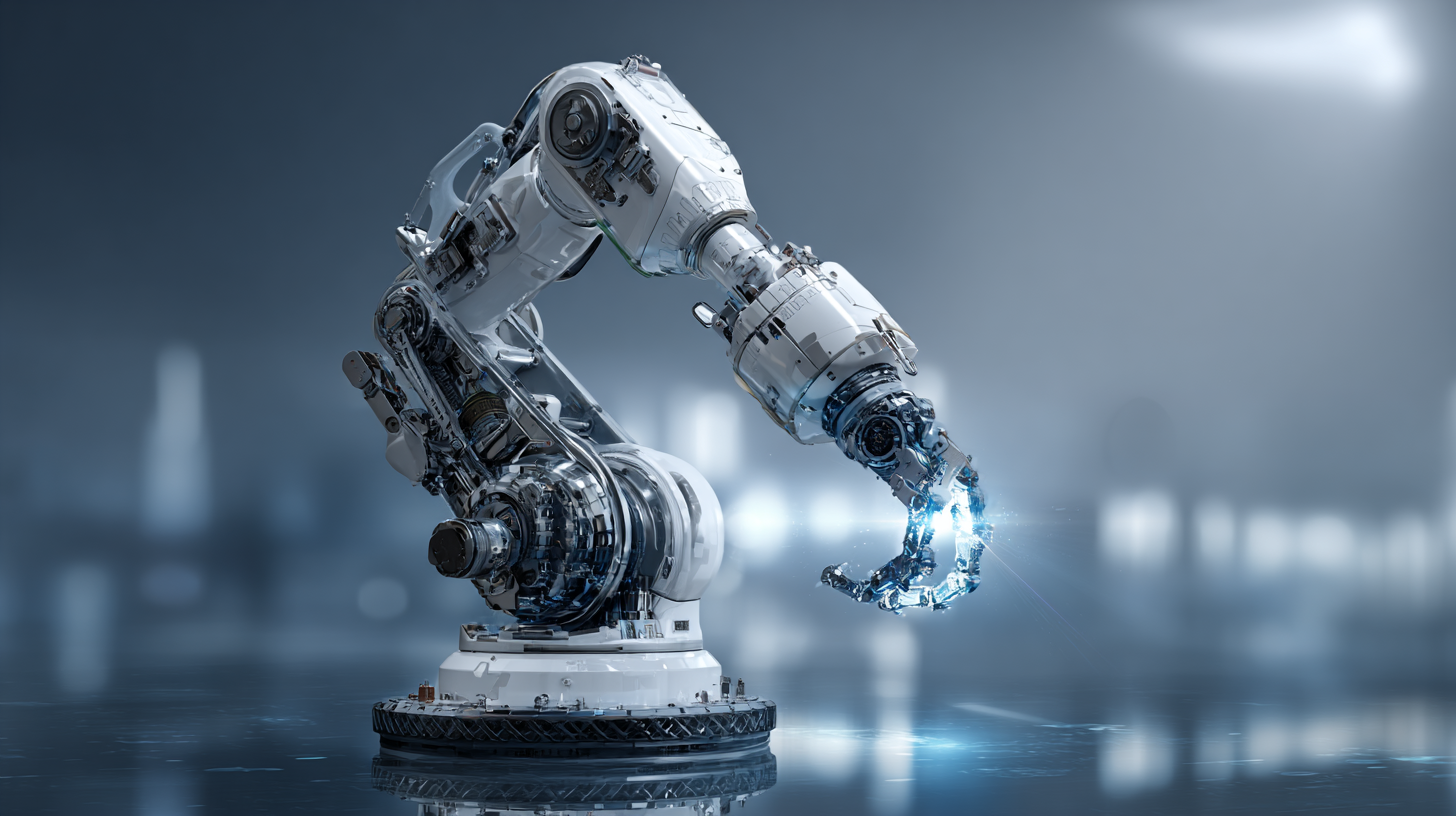

In 2023, the integration of robotics into logistics has transformed traditional supply chains into agile, efficient networks. Advanced robotic systems are streamlining operations by automating routine tasks such as sorting, packing, and inventory management. For instance, autonomous mobile robots (AMRs) navigate warehouses with precision, transporting goods from one point to another, thereby reducing manual labor and minimizing human error. This shift not only accelerates the flow of products but also enhances overall productivity.

Moreover, robotics technology is enabling real-time data collection and analysis throughout the supply chain. With the implementation of sensors and AI algorithms, logistics companies can monitor operations continuously, identifying bottlenecks and predicting demand with greater accuracy. This proactive approach allows businesses to optimize their resources and make informed decisions swiftly. As a result, companies are experiencing reduced operational costs and improved customer satisfaction, illustrating the critical role of robotics in modern supply chain management.

The agricultural sector is experiencing a transformative revolution thanks to the rise of next-generation robotic technologies. According to a report by MarketsandMarkets, the global agricultural robotics market is projected to reach $20 billion by 2025, growing at a CAGR of 24.1%. This rapid growth is largely driven by the adoption of advanced robotics in various farming practices, enhancing efficiency and productivity. Innovations such as autonomous tractors, drone-assisted irrigation, and intelligent harvesting systems are set to drastically change how crops are cultivated and managed.

One notable development in this field is the implementation of AI-powered precision agriculture robots that monitor crop health and soil conditions in real-time. A study by ResearchAndMarkets highlights that these robotic systems can increase yield by up to 30% by optimizing resource use and minimizing waste. Additionally, the integration of machine learning algorithms allows farmers to analyze vast amounts of data, leading to informed decision-making that significantly improves farming outcomes. This combination of robotics and AI not only boosts productivity but also contributes to sustainable farming practices, helping the industry meet the growing global food demand amidst environmental challenges.

The construction industry is experiencing a transformative shift with the integration of robotic innovations, paving the way for enhanced efficiency and safety on job sites. According to a recent report by McKinsey, robotics technology could increase productivity in construction by 15% to 30%, significantly reducing project timelines and costs. One such innovation is the use of autonomous drones, which are now capable of performing site surveys and inspections, providing real-time data and analytics that aid in better decision-making and resource allocation.

Another groundbreaking advancement is the implementation of robotic bricklayers, such as the SAM100. This machine can lay bricks at an impressive speed, completing tasks that would typically take human workers much longer, thereby addressing labor shortages in the industry. A study published by the World Economic Forum estimates that by 2025, automation could create up to 130 million new roles globally, of which many will be centered around managing and supporting robotic systems in construction. With these technologies, the future of construction is not only about building structures but also about building a more resilient and sustainable industry.