- sale@instructrobot.com

- Dallas, TX , United States

In recent years, robotic systems have transformed various industries. They enhance efficiency and productivity in manufacturing, logistics, and even healthcare. According to a report by McKinsey, automation could increase global productivity by 0.8 to 1.4 percent annually. This shift emphasizes the importance of optimizing robotic systems for maximum efficiency.

However, the road to achieving this efficiency is not without challenges. Many organizations struggle to integrate robotic systems seamlessly into existing workflows. A study by the International Federation of Robotics found that nearly 60% of companies face operational inefficiencies due to poorly optimized automation processes. There is a pressing need for continuous improvement and reassessment of these systems.

As we dive into the strategies for optimizing robotic systems, it is essential to recognize these imperfections. The landscape of automation is evolving, yet not all implementations are successful. Understanding the interplay between technology, human factors, and workflow is crucial. Addressing these elements thoughtfully can lead to substantial advancements in efficiency.

The realm of robotic systems optimization is evolving rapidly. One trend is the integration of machine learning algorithms. These algorithms help robots learn from data. They improve decision-making processes in real-time. For example, a robot can adjust its path based on obstacles it encounters. This flexibility can enhance efficiency. However, implementing machine learning requires careful planning.

Another trend is the focus on energy efficiency. Robots consume a lot of power. New designs aim to reduce energy waste. Companies are experimenting with lightweight materials. The right material can significantly lower energy needs. Yet, balancing durability and weight is challenging. Achieving this harmony requires ongoing testing and refinement.

Collaboration between machines is another emerging trend. Robots often work alongside humans. Effective communication between them can boost productivity. However, ensuring seamless interaction is complex. Compatibility issues can arise. Companies must address these challenges. Enhancing robot-to-robot communication is still a work in progress. Finding the right solutions can lead to better operational outcomes.

When measuring robotic efficiency, key performance indicators (KPIs) are essential. These metrics provide insight into how well robotic systems function. Common KPIs include uptime, throughput, and accuracy. Uptime refers to the amount of time robots operate without interruptions. High uptime translates to increased productivity.

Throughput measures the total output over a specific time frame. It's crucial for understanding how many tasks a robot completes. If throughput is low, it may indicate the need for process optimization. Accuracy is another important KPI. It tracks the precision of robotic actions. Inaccuracies can lead to errors, waste, and rework.

However, some operators overlook the significance of these metrics. Reliance on just one KPI can skew the overall understanding of efficiency. Additionally, regular review and adjustment of these KPIs are vital. Without reflection, systems may stagnate or decline in effectiveness. It's important to stay vigilant and adapt to changing conditions.

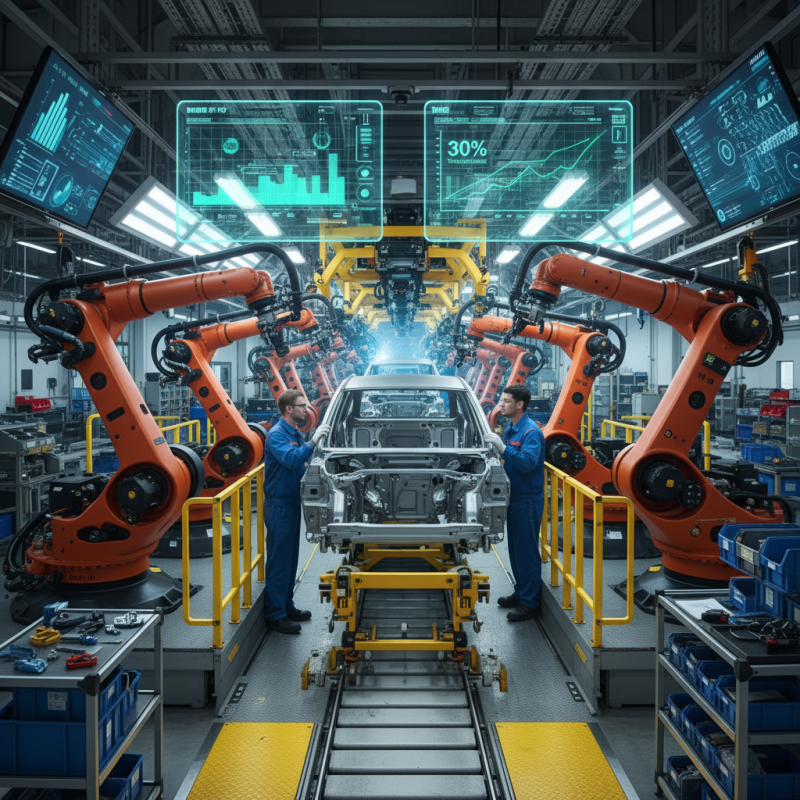

The integration of artificial intelligence (AI) and machine learning (ML) has transformed robotic operations remarkably. A report by the International Federation of Robotics indicates that AI-enhanced robots can increase operational efficiency by up to 30%. This improvement stems from their ability to analyze vast amounts of data quickly and adapt to changing conditions in real time. Robots equipped with machine learning algorithms can learn from their environment and optimize their movements, reducing energy consumption significantly.

However, challenges remain. Many organizations still struggle with the initial setup of AI models for robotics. Data quality and availability are critical factors. Often, companies find their data is fragmented or incomplete. This can hinder the training of effective AI models. Experts suggest that around 40% of AI projects fail due to poor data management practices. Furthermore, the learning curves associated with these technologies can cause delays in implementation.

Another area needing attention is the ethical implications of using AI in robotics. Concerns about job displacement and decision-making transparency persist. Evaluating the impact of robotic automation on the workforce is essential. Balancing efficiency gains with social responsibility poses a significant challenge. Addressing these issues may pave the way for more sustainable integration of AI and robotics.

In recent years, various industries have embraced robotic systems to enhance productivity. A prominent case study is found in the manufacturing sector. A mid-sized automotive firm adopted optimization strategies in its assembly lines. The change resulted in a 30% increase in throughput. This improvement exemplifies how data analytics can streamline operations. However, not all implementations yield success. Some firms reported minimal benefits due to poor data quality, highlighting the need for careful analysis.

Another relevant example comes from logistics. A large distribution center implemented a robotics system that utilized AI for inventory management. The outcome was impressive, with a 25% reduction in order-picking time. Yet, they also faced challenges. Workers reported discomfort with the new systems. Continuous training is essential but often overlooked. As a result, some systems fail to achieve their full potential.

These cases show the importance of customization. Each industry needs tailored solutions that fit specific operational demands. Optimization strategies must consider human factors. Balancing efficiency and employee satisfaction is crucial. Many organizations underestimate this connection. The path to maximizing robotic system efficiency includes both technical and human elements.

As robotic systems evolve, efficiency remains a vital focus. Researchers are exploring new paradigms to enhance performance. Innovations in artificial intelligence promise to transform the decision-making process of robots. Machine learning algorithms can adapt to environments, improving task execution. With real-time data processing, robots will adjust their actions swiftly. This can lead to better results in various industries, such as manufacturing and healthcare.

Emerging technologies, like collaborative robotics, pave the way for more seamless interactions. These robots work alongside humans, learning from their actions. This synergy could lead to new standards of efficiency. However, there are challenges. Ensuring safety in human-robot collaboration is critical and often overlooked. Developers must prioritize this aspect. Balancing complexity and usability will be a constant dilemma.

Another area of focus is energy efficiency. Innovations in battery technology are essential. Long-lasting batteries can reduce downtime significantly. Yet, the integration of such technology can be difficult. Not all components play well together. A holistic approach is necessary to overcome these obstacles. Transitioning from theoretical models to practical applications requires ongoing reflection and iteration.

| Innovation | Description | Efficiency Gain (%) | Implementation Time (months) |

|---|---|---|---|

| AI-Based Decision Making | Utilizing machine learning to enhance automation processes. | 20 | 6 |

| Energy Harvesting | Implementing systems that convert ambient energy into usable power. | 15 | 8 |

| Modular Robotics | Using interchangeable parts to enhance flexibility and reduce downtime. | 25 | 12 |

| Predictive Maintenance | Utilizing sensors and analytics to foresee and prevent failures. | 30 | 5 |

| Collaborative Robots (Cobots) | Designing robots that can work alongside humans safely. | 35 | 7 |