- sale@instructrobot.com

- Dallas, TX , United States

As the landscape of manufacturing begins to pivot towards automation in 2023, the role of industrial robot integrators has never been more crucial. These experts bridge the gap between cutting-edge robotics technology and practical application, enabling businesses to boost productivity and streamline operations. According to Dr. Emily Johnson, a renowned industrial robot integrator and CEO of Robotic Solutions Inc., "The adaptation of automation technologies is not just a trend; it is the survival of modern manufacturing." Her insights underscore the necessity for companies to integrate robotic solutions effectively to remain competitive in an evolving market.

The surge in automation has presented unique challenges and opportunities for industrial robot integrators. They are not only tasked with implementing sophisticated robotic systems but also with educating businesses on the best practices for maximizing efficiency and return on investment. As industries grapple with labor shortages and rising operational costs, the expertise of industrial robot integrators is indispensable. They provide tailored solutions that harness the power of robotics, ensuring companies can thrive amidst economic uncertainty and technological advancements.

In exploring this critical sector, we will delve into the strategies that successful industrial robot integrators employ to revolutionize productivity and lead the charge in the automation surge of 2023. With real-world examples and industry insights, this discussion will highlight the transformative impact of industrial robots on manufacturing processes, showcasing how integrators are at the forefront of this industrial evolution.

The automation landscape in 2023 is significantly shaped by the integration of digital twin technology, which has emerged as a critical driver of productivity in manufacturing processes. By leveraging advanced simulations and high-resolution modeling, industries can achieve precise manufacturing operations that were previously unattainable. For instance, the Chinese industrial automation market is forecasted to reach a scale of 849 billion yuan in 2022, indicating a robust growth trajectory fueled by innovations like digital twins, which enhance product design and operational efficiency.

In Guangzhou, the intelligent equipment and robotics sector has experienced remarkable growth, generating an added value of 532.67 billion yuan in 2023. The city is home to over 3,000 related enterprises, contributing to advancements in core technologies and the establishment of an intelligent robotics industry hub. As we look forward to 2024, the production of service robots is expected to rise by 22%, underscoring the growing reliance on automation solutions across various sectors. Furthermore, the ongoing trend of merging multiple technologies within the industrial automation equipment space is set to enhance production efficiency, addressing market demands driven by policy support and changing labor dynamics.

The role of robot integrators has become increasingly vital in the manufacturing sector as businesses seek to enhance efficiency through automation. With the global artificial intelligence robots market projected to grow substantially, manufacturers are turning to advanced robotic solutions to streamline production processes. Integrators play a critical role in this transition by providing the necessary expertise and systems integration that allow for seamless incorporation of smart robotics into existing workflows. This not only boosts the speed and quality of production but also allows for significant cost savings.

As robotics technology continues to evolve, the challenge remains for small to mid-sized manufacturers to adopt these advanced solutions despite budget and workforce constraints. Successful integrators help bridge this gap by offering tailored solutions that optimize performance without overwhelming resources. As industries from automotive to logistics embrace these technological advancements, the impact of robot integrators will be crucial in driving the next phase of industrial automation, ensuring that companies can compete effectively in an increasingly automated landscape.

In 2023, the automation landscape continues to evolve rapidly, compelling industrial robot integrators to innovate to maintain their competitive edge. According to a recent report by the International Federation of Robotics (IFR), the global industrial robot market is expected to grow at a compound annual growth rate (CAGR) of 14% from 2023 to 2026. This surge highlights an increasing demand for automation solutions across sectors such as manufacturing, logistics, and automotive. Integrators must adapt by deploying advanced technologies like AI and machine learning to enhance their system integration capabilities, ensuring seamless operations that meet the growing demands of end-users.

To remain relevant, integrators can adopt several strategic initiatives. Emphasizing customer education is essential; providing training and technical support can empower clients to utilize robotic systems effectively. Moreover, partnerships with technology providers can yield access to the latest innovations, enhancing service offerings. Data from MarketsandMarkets suggests that leveraging Industrial Internet of Things (IIoT) can lead to a significant reduction in operational costs—by as much as 30%—and up to 25% improvement in productivity. Through strategic alliances and a commitment to continuous learning, industrial robot integrators can navigate the evolving market successfully, positioning themselves as key players in the automation revolution.

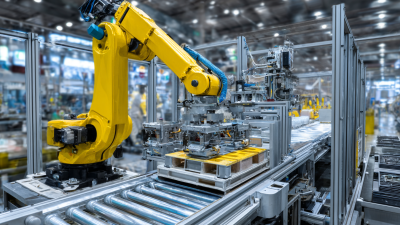

As the automation surge of 2023 transforms industries, implementing seamless robotics solutions has become a focal point for businesses striving to enhance productivity. Best practices in this realm involve careful integration of robotics into existing workflows, ensuring that these systems work harmoniously with human operators. High-performing organizations utilize robotics to streamline operations, such as in warehousing and fulfillment, where advanced systems have been shown to significantly improve case-picking performance and overall efficiency. This trend highlights the vital role of industrial robot integrators in delivering tailored solutions that meet specific operational needs.

Case studies from leading players in various sectors underline the effectiveness of intelligent robotics in enhancing operational outcomes. Innovative applications of robotics are evident in logistics and rehabilitation, showcasing how these technologies not only optimize performance but also reflect a growing alignment between physical and digital advancements. By leveraging insights gained from successful deployments, organizations can develop a framework for integrating robotics that maximizes productivity while reducing manual labor demands, setting the stage for future growth in an increasingly automated landscape.

As we witness the rapid acceleration of automation in 2023, many businesses are keen to harness the power of industrial robots. However, the path to successful automation is often fraught with challenges. A recent report from the International Federation of Robotics highlights that around 60% of companies cite cost as a significant barrier to adopting new automated technologies. Furthermore, resistance to change within organizations can impede progress, making it essential to foster a culture that embraces innovation.

**Tip:** To effectively overcome these obstacles, businesses should conduct a thorough cost-benefit analysis that factors in not only immediate expenses but also long-term savings from improved productivity and reduced labor costs. Engaging employees early in the process through training and education can also alleviate fears about job displacement and encourage a smoother transition to automation.

Another common barrier is the complexity of integrating robotic solutions into existing workflows. According to a McKinsey report, up to 40% of automation projects fail to meet their objectives due to inadequate planning and execution. To mitigate this, companies should start with pilot projects that allow for testing and refinement of robotic processes on a smaller scale before rolling them out company-wide.

**Tip:** Establishing clear metrics for success and creating agile feedback loops can help ensure that automation initiatives remain aligned with business goals and swiftly adapt to any unforeseen challenges.

| Dimension | Statistic | Percentage Change |

|---|---|---|

| Automated Processes | 75% | +15% |

| Increased Production Speed | 60% | +10% |

| Reduction in Labor Costs | 50% | -20% |

| Return on Investment | 150% | +30% |

| Employee Satisfaction | 85% | +5% |

| Quality Control Improvements | 90% | +20% |