- sale@instructrobot.com

- Dallas, TX , United States

In today's fast-paced industrial landscape, the role of a robot integrator has become crucial. Experts like John Smith, a leading professional in automation, emphasize its importance: "A robot integrator bridges technology and application." This highlights the integrator's vital role in ensuring robots meet specific operational needs.

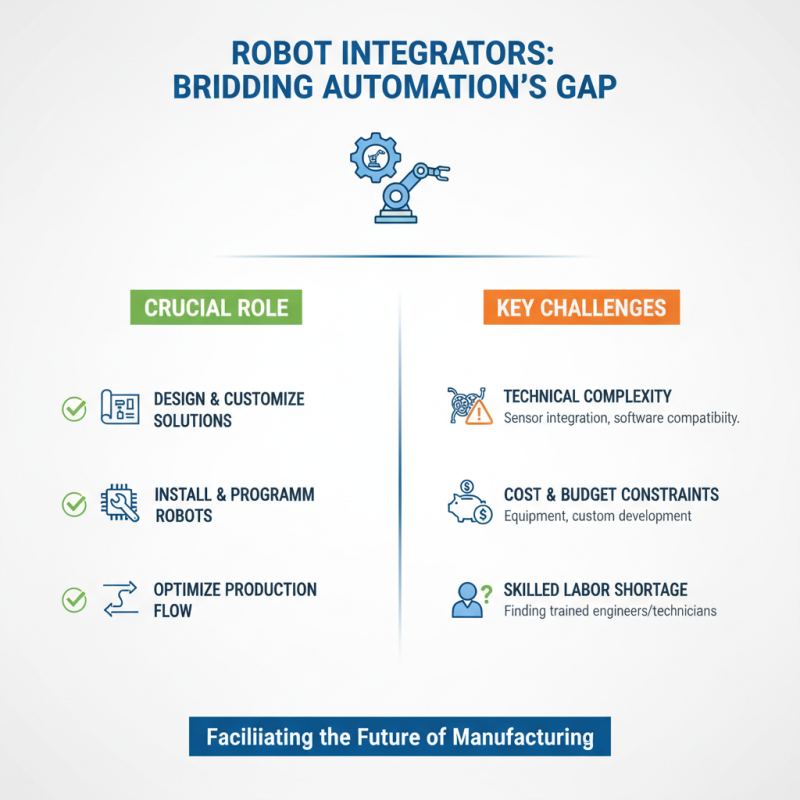

Robot integrators tailor solutions for various industries. They combine hardware, software, and expertise to create functional robotic systems. However, integration is not without challenges. Misunderstanding of requirements can lead to misalignment, resulting in inefficiencies. Integrators must adapt to unique business environments while managing complex integrations.

Moreover, the impact of robot integration on automation is profound. It can enhance productivity and optimize workflows. Yet, companies must reflect on their readiness for such transformations. Change often brings uncertainty. A well-planned integration strategy can mitigate risks but may still face hurdles. A successful robot integrator can make all the difference in navigating this intricate landscape.

A robot integrator plays a crucial role in the world of automation. They are responsible for designing, implementing, and managing robotic systems. This includes integrating robots into existing processes. A successful robot integrator understands both technology and the specific needs of a business.

In this complex landscape, the integrator ensures robots operate seamlessly with other machinery. Their expertise reduces downtime and maximizes efficiency. The process, however, is not without challenges. There can be compatibility issues or unexpected delays in installation, which require careful planning.

Tips: Choose an integrator who offers tailored solutions. Consider their experience in your industry. Evaluate their past projects for success stories. A good fit is vital for maximizing automation benefits.

Communication is also key. Regular updates and feedback help identify problems early. This two-way dialogue fosters a stronger working relationship. Sometimes, it might feel frustrating when adjustments are needed. Embrace these moments; they often lead to better results in the long run.

| Dimension | Description |

|---|---|

| Integration Capacity | The ability to connect robots with existing systems and machinery. |

| Technical Expertise | Specialized knowledge in robotics and automation technologies. |

| Project Management | Skills to manage projects from planning to execution and delivery. |

| Customization Services | Tailoring solutions to fit specific operational needs of businesses. |

| Support and Maintenance | Providing ongoing support and maintenance for robotic systems. |

| Cost Efficiency | Reducing operational costs through optimized automation solutions. |

| Scalability | Ability to expand automation efforts as business grows. |

| Return on Investment | Measuring the financial benefits from automation investments. |

A robot integrator plays a crucial role in modern manufacturing systems. Their primary responsibility is to design, implement, and maintain automated solutions. This requires a deep understanding of both robotics and the specific manufacturing processes they enhance. Whether it's assembling parts or packaging products, the integrator ensures robots fit seamlessly into workflows.

Collaboration is vital. Robot integrators work closely with engineers and operators. They analyze workflows to identify areas for automation. This might involve programming robots or adapting them to new tasks. Deviations in process can highlight areas needing improvement. Mistakes can lead to inefficiencies, reminding integrators that fine-tuning is essential.

Communication is key throughout the process. Integrators must explain technical details in simple terms. They also need feedback from the workforce. Understanding their concerns helps refine the automation strategy. Acknowledging the human element in automation is important. After all, technology should enhance productivity, not complicate it. Each step in the integration journey offers lessons, pushing the boundaries of what robots can achieve in manufacturing.

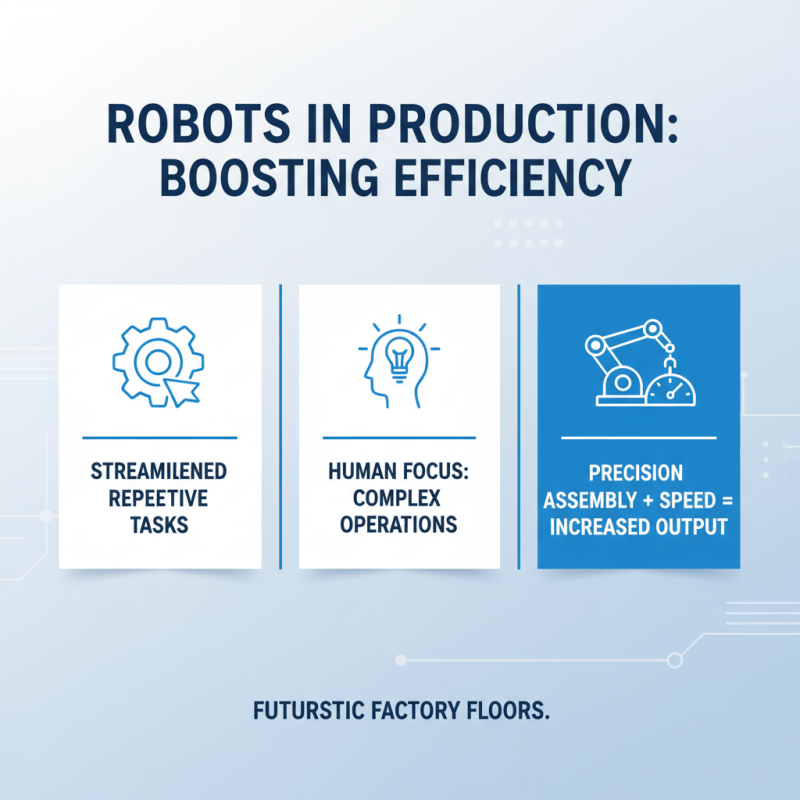

The integration of robots into production lines can significantly enhance efficiency. Robots streamline repetitive tasks, allowing human workers to focus on complex operations. For instance, a robot can handle assembly with precision, reducing errors and increasing speed. In a busy factory, this can lead to a notable uptick in output.

Cost reduction is another vital benefit of robot integration. Automating processes can lower labor costs and minimize waste. By using robots for tasks like packaging or sorting, businesses can save on material and time. However, the initial setup costs may be high. Companies must carefully weigh potential savings against this upfront investment.

Yet, not all outcomes are positive. Some workers feel insecure about their roles. This can lead to morale issues and decreased productivity. Ensuring that human workers are reassured about their value is crucial. Moreover, maintenance of robotic systems adds ongoing costs, creating another layer of complexity. Balancing automation with human labor requires careful planning and reflection.

Robot integrators play a crucial role in automation projects. They bridge the gap between robotic technology and practical application. However, they face various challenges that can impact the success of these initiatives.

One significant challenge is adapting to diverse client needs. Each project varies in scale and requirements. This variability can lead to difficulties in standardizing solutions. Integrators must balance flexibility with efficiency. It’s not easy to meet unique demands while staying on schedule. Resource allocation frequently requires careful consideration. Misjudgments can lead to delays or wasted resources.

Another challenge is the constant evolution of technology. New robotic systems emerge rapidly. Keeping up with these advancements is demanding. Integrators must continuously learn and adapt. A lack of training can hinder project outcomes. Communication also poses hurdles. Effective collaboration among teams is essential for success. Misunderstandings can lead to errors. It’s vital to create a culture of open dialogue, but this is often overlooked.

The landscape of automation is rapidly changing. With the rise of Industry 4.0, robot integration is becoming essential. This trend focuses on connecting robotics with advanced technologies like IoT, AI, and big data. Companies that adapt to these changes can optimize performance. However, the integration process is often complex and requires careful planning.

Many industries are exploring how robotics can enhance efficiency. The implementation of robots can streamline operations and reduce costs. Still, organizations must consider the challenges. For instance, integrating different systems may lead to technical issues. It’s crucial to evaluate existing setups before making drastic changes. Some companies struggle with outdated practices, which can hinder progress.

As automation becomes more prevalent, training employees is vital. Workers need to understand how to interact with robots. This creates a learning curve that can be daunting. Managers may find resistance among staff. Navigating this cultural shift is as important as the technology itself. The future of robot integration is promising, but reflection on its implementation is necessary for success.