- sale@instructrobot.com

- Dallas, TX , United States

Choosing the right robot palletizer can be a game-changer for your business. These machines streamline the process of stacking goods onto pallets, saving time and labor costs. However, making the right choice requires careful consideration of various factors.

Many businesses overlook the specific needs of their production line. Understanding your product type is crucial. Different robot palletizers handle diverse shapes and weights. This affects the efficiency of your operations. Additionally, the layout of your workspace must be considered. A suitable robot palletizer should fit seamlessly within your existing setup.

Investing in a robot palletizer involves weighing not just the initial costs but also long-term efficiency. Cheaper options may cost more in maintenance or may not meet your volume needs. Reflecting on your current and future requirements will help in making a sound decision. Consider the versatility of the robot palletizer. It should adapt as your business grows and changes.

When selecting a robot palletizer, consider your production needs carefully. Evaluate the weight and size of the products you'll be handling. This information will help determine the specifications needed for the robot. Flexibility in operation is also crucial. A system that adapts to different package types can save time and reduce costs.

Another essential factor is the environment where the robot will operate. Will it function in a cold or wet area? Understanding these conditions can affect the robot's lifespan and efficiency.

Training staff to troubleshoot and maintain the robot should not be overlooked. It's important to invest in this aspect for long-term success.

Cost considerations are vital too. It's easy to fall for cheaper options initially, but they can lead to higher maintenance costs later. Reflecting on these ongoing costs can prevent future budget strains.

Robot palletizing technology is evolving. Keeping an eye on future trends may offer insights into better returning options. A thoughtful selection process today can make a significant difference tomorrow.

When it comes to choosing a robot palletizer, understanding the types available is crucial. There are various types, including articulated, Cartesian, and delta palletizers. Each type has its unique features and benefits. Articulated robot palletizers are versatile and can handle complex stacking patterns. They work well in tight spaces. Delta palletizers are ideal for high-speed operations, especially in the food and beverage industry. Each type serves different needs.

Tip: Assess your production volume before choosing a model. This will help you select a palletizer that meets your output requirements. Likewise, consider the size and weight of the products. Not all palletizers are equipped to handle heavy loads. Remember, a mismatch can lead to inefficiency.

Another type is collaborative robots, or cobots. They work alongside human operators for better flexibility. However, they may not be suitable for all tasks. Evaluate potential workflow challenges. If there’s too much human-robot interaction, safety becomes a concern. You might find it's better to opt for a more traditional model.

Each type of robot palletizer offers distinct advantages and disadvantages. Take time to reflect on your production environment. Understand your specific needs before making a decision. This process can save time and costs in the long run.

| Aspect | Details |

|---|---|

| Type of Robot | Articulated, SCARA, Delta |

| Payload Capacity | Up to 1000 kg |

| Speed | 200-300 picks per hour |

| Footprint Size | Small, Medium, Large |

| Compatibility | Multiple conveyor systems |

| Programming Ease | User-friendly interfaces & APIs |

| Safety Features | Emergency stop, light curtain |

| Maintenance | Low maintenance, easy to service |

| Cost | Varies from $50,000 to $300,000 |

| Support & Training | On-site and online training options |

When selecting a robot palletizer, it's vital to consider payload capacity and throughput. Payload capacity refers to how much weight the robot can handle. This varies significantly between models. Analyze your typical product weights and sizes. It's important to match the robot's capabilities to your operational needs. A mismatch could lead to inefficiencies.

Throughput requirements are equally critical. This measures how many loads a robot can handle in a given time. Assess your production schedule. If demand fluctuates, you may need a robot that adapts to different speeds. Sometimes, a higher throughput can strain the system. This might lead to breakdowns or maintenance issues. Striking the right balance can be challenging but is necessary for long-term efficiency.

Additionally, consider the layout of your facility. Space constraints can affect the choice of palletizer. A larger model may not fit in tight spaces, leading to workflow disruptions. Reflect on your future growth as well. You wouldn’t want to outgrow your equipment too quickly. While it’s tempting to opt for the latest features, practicality often prevails. Identifying the right specifications tailored to your needs is crucial for effective operation.

When selecting a robot palletizer, flexibility and adaptability are crucial. Many factories face changing product lines and variable production demands. A study by the International Federation of Robotics (IFR) indicates that about 66% of manufacturers prioritize adaptable automation solutions. This flexibility allows them to switch between different products seamlessly, reducing downtime.

It's essential to assess how a robot palletizer handles various payloads and box sizes. According to recent market analysis, 70% of companies reported needing systems that can accommodate diverse products. A robot that can quickly change end-of-arm tooling can dramatically enhance its efficiency. However, choosing a robot that is highly adaptable may lead to increased complexity. This could hinder ease of operation and maintenance.

Also, integration with existing systems should not be overlooked. Many businesses underestimate the challenges of this process. Reports from industry consultants suggest that 30% of implementations encounter issues during integration. Addressing these potential difficulties early can save time and resources in the long run. In considering flexibility, it's vital to reflect on whether a robot's capabilities truly align with your operational needs.

This chart illustrates the importance of key factors when selecting a robot palletizer, focusing on flexibility and adaptability. Each factor contributes to the overall effectiveness and efficiency of the robot system.

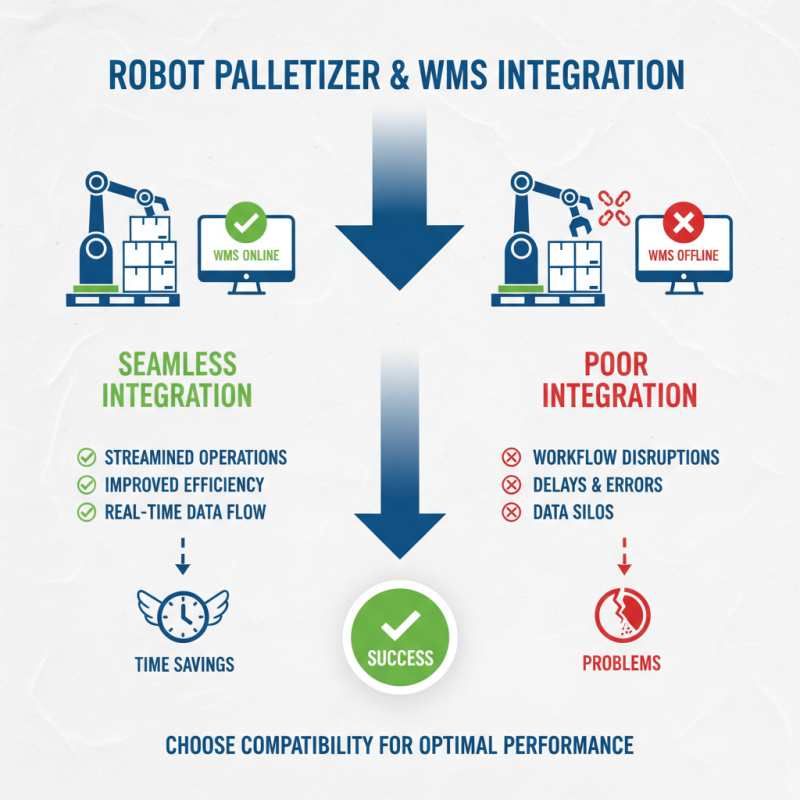

When selecting a robot palletizer, integrating it with your existing warehouse management system (WMS) is crucial. A seamless connection helps streamline operations. If the palletizer doesn't sync well, your workflow could suffer. Delays might occur, wasting valuable time.

Consider how the robot will interact with your WMS. It should easily exchange data. For example, inventory levels and order status updates must be real-time. This integration prevents potential bottlenecks. Think about your current setup: will the new robot work well with your existing software?

Before deciding, remember to evaluate your specific needs. No two warehouses are the same. Ensure the palletizer can adapt to your current processes. Testing the system with sample tasks might reveal issues. You might discover that your expectations don’t align with reality. It’s essential to reflect on these points as you make your choice. With the right fit, efficiency can improve significantly.