- sale@instructrobot.com

- Dallas, TX , United States

As we venture further into the era of automation, the role of manufacturing robots becomes increasingly pivotal in reshaping industries and enhancing productivity. The 2025 landscape reveals a wealth of technological advancements and innovative designs that are set to revolutionize the manufacturing sector. These top 10 manufacturing robots exemplify the intersection of efficiency and intelligence, facilitating processes that were once deemed labor-intensive and time-consuming.

From collaborative robots, or cobots, that work safely alongside human operators, to high-speed autonomous units capable of performing intricate tasks with unparalleled precision, the future of manufacturing is undeniably linked to these machines. As we explore these cutting-edge manufacturing robots, we will uncover how they are transforming not only production lines but also the way businesses operate, making them more agile and adaptable to market demands. Embracing these advancements, manufacturers will be better equipped to navigate the challenges of an ever-evolving economic landscape while ensuring sustainable growth and enhanced competitiveness.

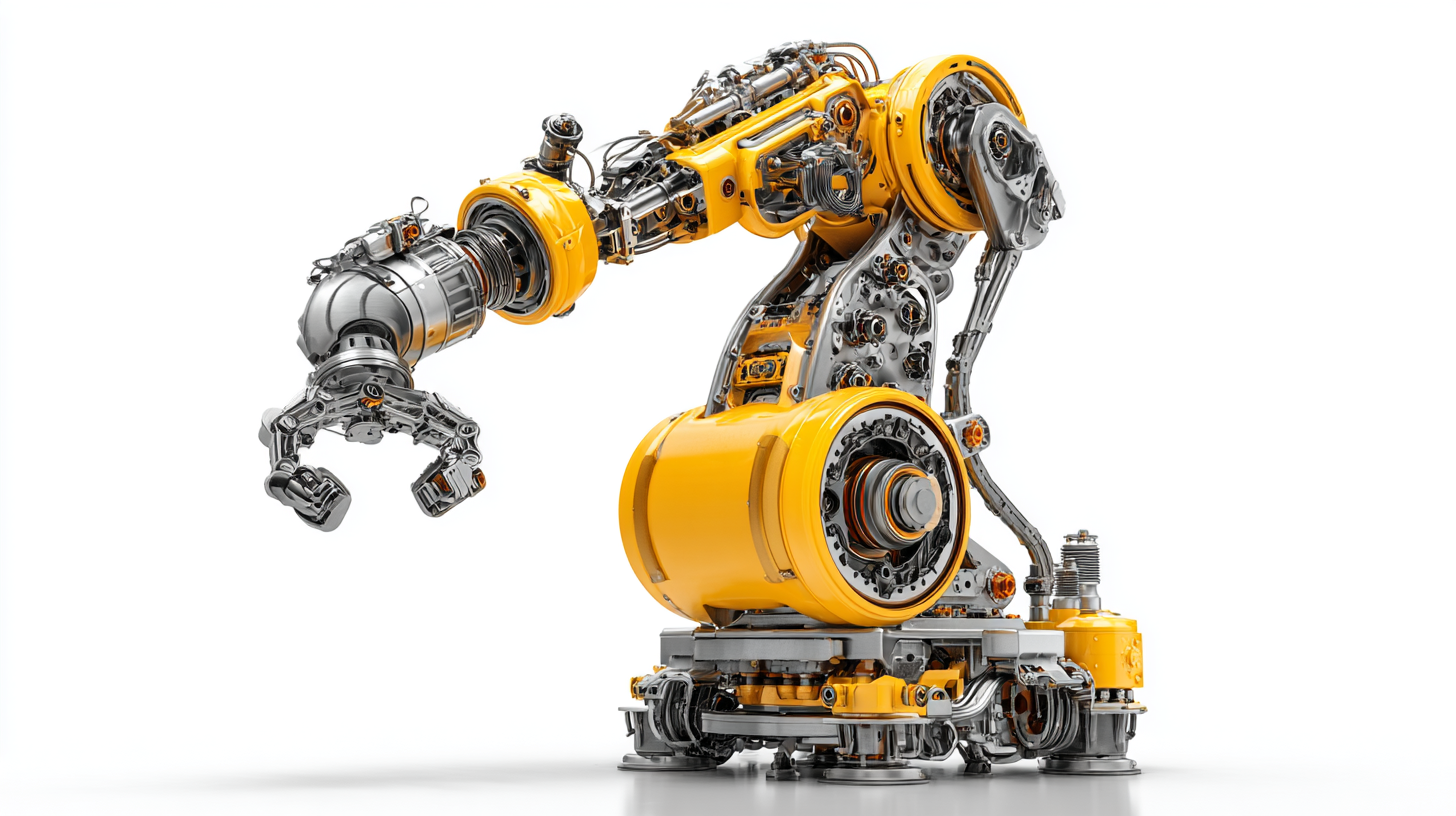

The infusion of advanced articulated robots into manufacturing automation marks a significant leap towards precision and efficiency. These robots, designed with multiple joints and degrees of freedom, mimic the fluid motions of the human arm, allowing them to perform intricate tasks that were once considered too complex for machines. Their ability to adapt to various manufacturing processes enhances not only the speed of production but also the quality of the outputs, as they can consistently execute detailed operations with minimal error.

Moreover, the integration of sophisticated sensors and AI-driven algorithms enables these robots to learn from their environment and improve over time. This adaptation capability ensures that they can handle a variety of materials and components, shifting seamlessly between tasks on the production line. As industries face increasing demands for customization and rapid turnaround times, advanced articulated robots provide a solution that balances flexibility with high-precision performance, driving the evolution of manufacturing into a smarter and more automated future.

This chart showcases the predicted market share percentage of the top 10 most impactful advanced articulated robots in the manufacturing sector for 2025. The data reflects their contribution to efficiency, precision, and overall transformation in automation.

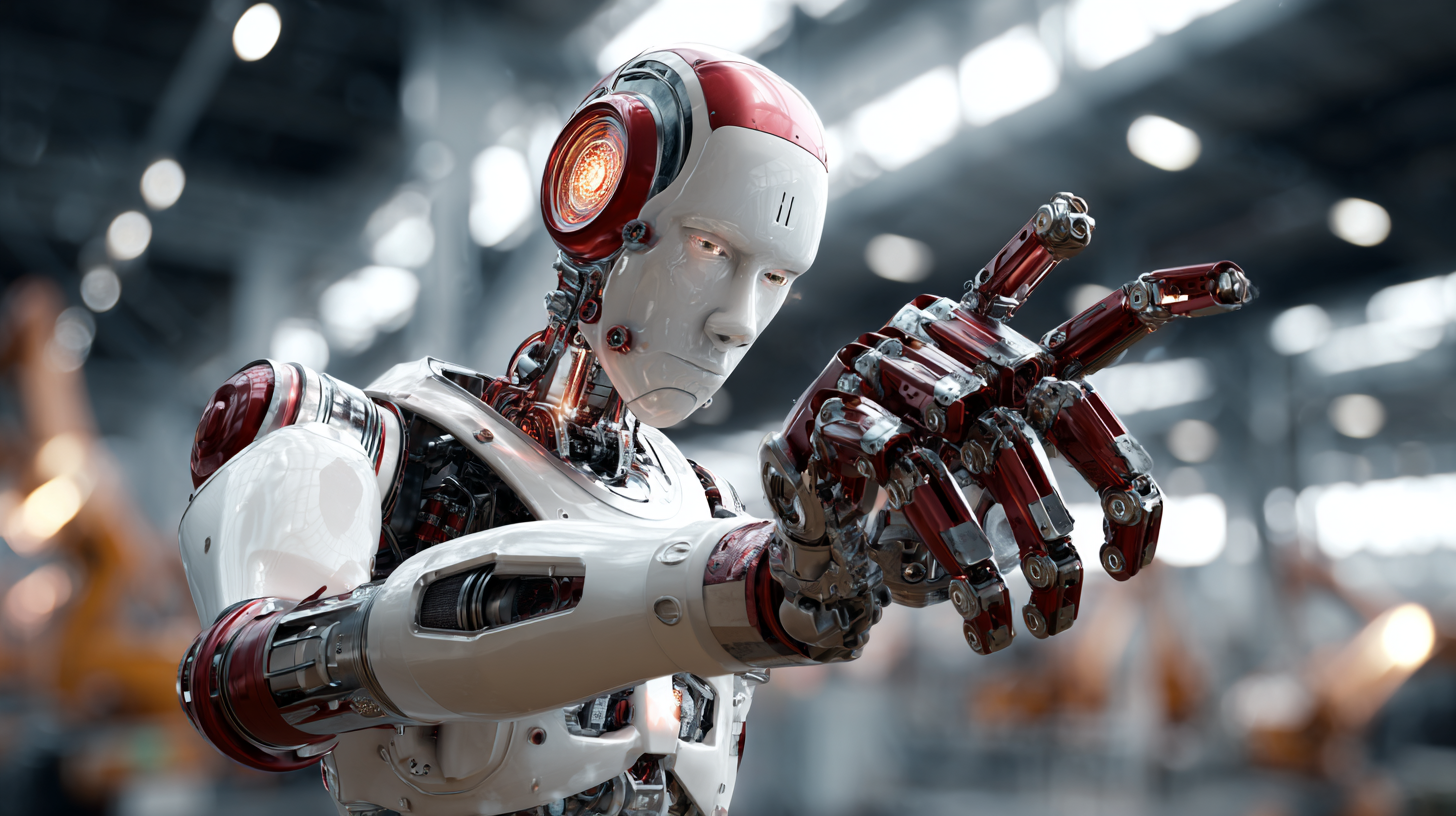

In the evolving landscape of manufacturing, collaborative robots, or cobots, are emerging as pivotal players in enhancing human-machine interactions. Designed to work alongside human operators, these advanced robots prioritize safety and efficiency, allowing them to share tasks without the need for extensive safety barriers. This direct interaction not only accelerates production but also fosters a more dynamic work environment.

As industries increasingly adopt cobots, the advantages become clear. They can handle repetitive and labor-intensive tasks, freeing human workers to focus on more complex and creative aspects of production. This synergy not only boosts overall productivity but also improves job satisfaction, as employees are empowered to engage in tasks that require critical thinking and problem-solving skills. Moreover, the adaptability of cobots allows easy integration into existing workflows, making them a cost-effective solution for manufacturers looking to modernize operations and increase competitiveness in the automation sector.

The integration of AI-powered robotics in manufacturing processes is fundamentally transforming the industry by driving speed and accuracy like never before. As the robotics technology market surges towards a projected USD 375.95 billion by 2025, companies are increasingly turning to smart robots that leverage advanced algorithms and machine learning capabilities. These robots are designed to learn complex tasks with remarkable precision, significantly enhancing production efficiency. For instance, research teams have developed innovative methods that allow robots to assemble intricate parts quickly and accurately, making them invaluable assets in modern manufacturing environments.

Moreover, AI in manufacturing extends beyond task execution. It plays a pivotal role in optimizing the entire production cycle. Smart robots equipped with machine vision are not only streamlining operations but also improving quality control and adaptability to varying production demands. This technological evolution is particularly evident in sectors like electric vehicle battery production, where enhanced precision and efficiency are essential. As manufacturers embrace AI-driven solutions, they are poised to redefine operational standards, resulting in higher productivity levels and reduced costs across the board.

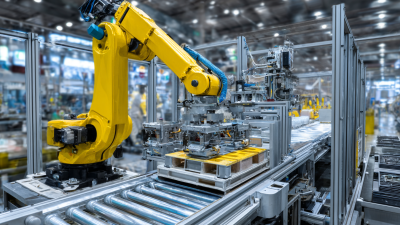

The landscape of automation is rapidly evolving, particularly in the realm of material handling robots. These innovative machines are designed to optimize workflow and significantly reduce downtime in manufacturing environments. As organizations seek to enhance operational efficiency, the global material handling equipment market is projected to surpass $400.6 billion, driven by the increasing demand for automation and advanced robotics technologies. A report highlights that the adoption of automated solutions not only streamlines processes but also reduces labor costs and minimizes human error, further propelling productivity.

In parallel, the global automotive robotics market is anticipated to reach $22.49 billion by 2033, underscoring the growing impact of electric vehicle adoption and Industry 4.0 integration. As companies integrate AI and robotics into their logistics and supply chains, they are reaping substantial benefits. AI applications in warehouse management enhance product placement and refine picking patterns, creating a seamless synergy in operations. This transformative shift not only boosts efficiency but also ensures that companies can meet the increasing demand from consumers, thus positioning them for success in a highly competitive market.

In 2025, the manufacturing sector is poised to undergo significant transformations, primarily driven by customizable robotics solutions that cater to the diverse demands of the industry. According to a recent report by MarketsandMarkets, the global industrial robotics market is expected to reach $75 billion by 2025, growing at a CAGR of 10.5% from 2020. This surge highlights the need for adaptive manufacturing environments where robots can be programmed or configured to perform a variety of tasks, thereby enhancing efficiency and flexibility in production lines.

As manufacturers increasingly seek tailored automation solutions, collaborative robots, or cobots, are gaining traction. Industry studies indicate that cobots are projected to account for up to 34% of the total robot market by 2025. This rise is attributed to their ability to work alongside human operators safely and intuitively, fostering an environment where customization and rapid reconfiguration are essential. By integrating advanced AI and machine learning algorithms, manufacturers can ensure that these robots meet specific operational needs, thereby maximizing productivity while minimizing downtime. The shift towards customizable robotics not only addresses current manufacturing challenges but also paves the way for more resilient and adaptive industrial ecosystems.

| Robot Model | Payload Capacity (kg) | Reach (mm) | Customization Level | Application Areas |

|---|---|---|---|---|

| Model A | 100 | 1500 | High | Assembly, Welding |

| Model B | 250 | 2000 | Medium | Packaging, Palletizing |

| Model C | 150 | 1800 | High | Machine Tending, Inspection |

| Model D | 80 | 1200 | Low | Quality Control, Sorting |

| Model E | 300 | 2500 | Medium | Heavy Lifting, Construction |

| Model F | 60 | 1000 | High | Electronics Assembly |

| Model G | 90 | 1400 | Low | Food and Beverage |

| Model H | 120 | 1600 | Medium | Medical Devices, Lab Automation |

| Model I | 200 | 2200 | High | Automotive, Aerospace |

| Model J | 70 | 1100 | Low | Textiles, Apparel |